- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

Dehumidifiers for Animal Feed Preservation: Optimal Solutions for Quality & Profit

12/06/2025

Dehumidifiers for Animal Feed Preservation: Optimal Solutions for Quality & Profit

In modern animal husbandry, proper feed preservation plays a crucial role, directly affecting animal health and determining the economic efficiency of the entire farm. Animal feed, especially grains, powders, or nutrient-rich mixtures, is highly susceptible to high humidity in the environment. When humidity exceeds acceptable limits, harmful molds and bacteria proliferate, leading to significant quality degradation, spoilage, and even the production of dangerous toxins. To thoroughly address this issue, industrial dehumidifiers are the optimal solution, providing superior efficiency in controlling the storage environment.

Why Use Dehumidifiers for Animal Feed Preservation?

Risks from High Humidity

- Mold and bacteria growth, toxin production: High humidity is an ideal environment for molds and bacteria to thrive, especially those producing dangerous toxins like Aflatoxin. These toxins are extremely hazardous, potentially causing acute poisoning, weakened immunity, and even death in livestock, leading to severe economic losses. (Source: FAO - Feed Quality)

- Nutrient reduction, affecting animal health: Moldy feed loses its inherent nutritional value, leading to poor absorption by animals, increased risk of disease, and direct impact on livestock productivity (slow growth, reduced milk, egg, meat production).

- Caking of feed, difficult storage, and spoilage: When humidity increases, powders, meals, and grains in the feed easily absorb moisture, leading to caking, clogging in automatic feeding systems, and increased waste.

- Packaging damage, increased costs: Feed packaging can also become moldy and deteriorated, losing its ability to protect the product inside, resulting in costly replacement or disposal.

Superior Benefits of DeAir Dehumidifiers

- Optimal humidity control, preventing mold and bacteria: Dehumidifiers maintain ideal humidity levels in the warehouse, creating a dry environment unsuitable for the proliferation of harmful agents.

- Preserving nutritional quality of feed: By controlling humidity, dehumidifiers help feed retain its freshness and stable nutrient content, ensuring animals receive sufficient energy and essential nutrients.

- Extending storage time, reducing waste: Low humidity helps prolong feed storage, minimizing spoilage, rancidity, and waste due to moisture, contributing to optimal resource utilization.

- Ensuring animal feed safety and hygiene: Feed stored in dry, clean conditions reduces the risk of contamination, ensuring animal health and producing safer livestock products for consumers.

- Optimizing production costs and increasing farm profits: Reduced feed waste, lower treatment costs for sick animals, and enhanced overall productivity directly contribute to increased profits for livestock businesses.

Types of Animal Feed and Their Humidity Requirements

Each type of animal feed has specific humidity requirements to ensure optimal quality and storage time. Here are some typical examples:

- Grain-based feed (corn, rice, soybeans, pellets): The ideal humidity is typically below 14%. Higher humidity can easily lead to mold growth, insect infestations, and reduced nutritional value. (Source: Feedipedia - Feed Storage)

- Silage: Although fresh feed, after ensiling, humidity needs to be well-controlled to prevent unwanted fermentation or bacterial contamination.

- Supplements (premixes, vitamins, minerals): These products often require very low humidity, sometimes below 10%, to maintain their biological activity and prevent caking or deterioration.

- Fish meal, meat meal: Require humidity below 10% to prevent oxidation, rancidity, and microbial growth.

Suitable Dehumidifier Models for Animal Feed Preservation from DeAir

DeAir proudly offers a diverse range of industrial dehumidifiers and dryers, specifically designed to meet the stringent demands of the animal husbandry industry:

1. Heat-Pump Industrial Dehumidifiers DeAir.RE

Models like DeAir.RE-60, DeAir.RE-300, DeAir.RE-600 (1 phase) or DeAir.RE-1200 (3 phase) belonging to the Heat-Pump Dehumidifier DeAir.RE series are ideal for large-scale animal feed storage facilities. With advanced Heat-Pump technology, these machines not only offer superior dehumidification capacity but also are extremely energy-efficient, significantly reducing operating costs.

Specifically, the Stainless Steel Heat-Pump Dehumidifier DeAir.RE-H series (e.g., DeAir.RE-150H INOX, DeAir.RE-300H INOX, DeAir.RE-600H INOX) is a perfect choice for environments requiring high hygiene and corrosion resistance, ensuring maximum safety for animal feed.

Electricity Saving Calculation with Heat-Pump Dehumidifiers

Heat-Pump technology in Heat-Pump Dehumidifiers DeAir.RE outperforms conventional condensing machines by utilizing heat from the condensation process to reheat the dehumidified air. This results in significantly higher energy efficiency. Heat-Pump dehumidifiers typically have a COP (Coefficient of Performance) ranging from 2.5 - 4.0, whereas conventional condensing dehumidifiers usually have a COP from 1.8 - 2.5. This means that for the same amount of electricity consumed, a Heat-Pump machine can remove a much greater amount of moisture, while also operating more effectively at lower temperatures and causing less cooling to the surrounding environment.

For example:

Consider a large-capacity industrial dehumidification system like the DeAir.RE-600 (1 phase) with a power consumption of 9.2 kW. If operating 24/7, the monthly electricity cost would be: 9.2 kW * 24 hours/day * 30 days/month * electricity price (e.g., 2,500 VND/kWh) = 16,560,000 VND. Compared to a conventional dehumidifier of equivalent capacity that might consume 15-20% more, the annual savings could amount to tens of millions of VND, helping businesses optimize long-term operating costs.

2. Heat-Pump Industrial Dryers Daxwell

For farms that self-produce or process animal feed, Heat-Pump Dryer Daxwell (e.g., DX-300S, DX-600M, DX-1200D) is an indispensable solution. Daxwell dryers utilize heat pump technology, allowing precise control of temperature and humidity during the drying process. This helps preserve the full nutritional content and quality of raw materials like corn, rice, soybeans, or processed products, while also providing superior energy savings.

3. Rotor Dehumidification Equipment Dezenno

In cases requiring extremely precise humidity control or very low humidity levels (below 40%), the Rotor Dehumidifier Dezenno series (e.g., Dezenno 320CMH - 1200CMH, Dezenno 1500CMH - 18000CMH) is a superior choice. Adsorption rotor technology effectively removes moisture even at low dew points, ideal for high-end feed storage facilities or areas requiring strict environmental control.

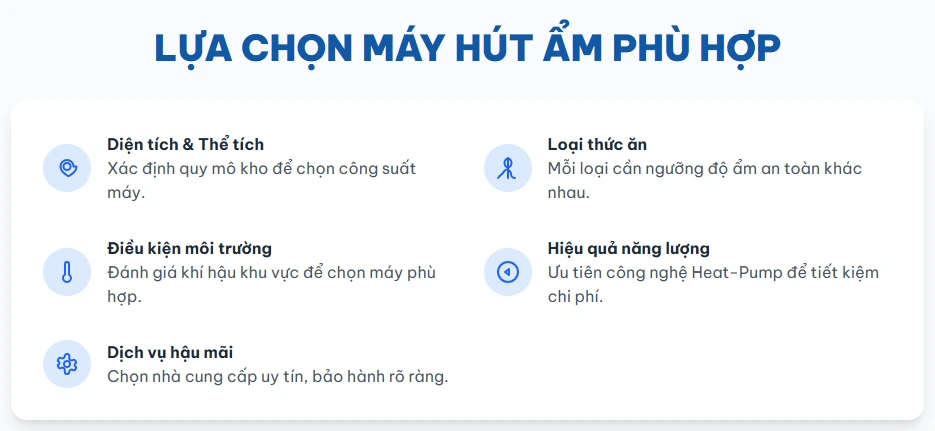

Factors to Consider When Choosing a Dehumidifier

To select the most suitable dehumidifier for animal feed preservation, you need to consider the following factors:

- Space area and volume: Accurately determine the size of the warehouse or factory to choose a machine with appropriate capacity.

- Type of animal feed and humidity requirements: Each type of feed has a different safe humidity threshold. It is necessary to understand specific requirements to maintain an ideal environment.

- Ambient temperature and humidity: Evaluate the local climate conditions to select a machine capable of operating effectively within that temperature and humidity range.

- Energy efficiency: Prioritize models using Heat Pump technology for electricity savings and reduced long-term operating costs.

- After-sales service: Choose a reputable provider with clear warranty and maintenance policies and professional technical support like DeAir.

Comprehensive Solutions from DeAir

With extensive experience and expertise in humidity and temperature control, DeAir is committed to providing comprehensive and optimal solutions for animal feed preservation. Our team of engineers will professionally consult, design, install, and maintain humidity control systems, ensuring maximum efficiency.

DeAir not only supplies high-quality products, utilizing the latest technologies such as Heat Pump and Rotor, but also focuses on after-sales service. We offer regular maintenance packages, prompt repair services, and commit to transparency in pricing.

Conclusion

Investing in an industrial dehumidifier is a strategic decision that brings sustainable benefits to the animal husbandry industry. Effective humidity control not only protects feed quality and prevents diseases but also contributes to increased productivity and maximized profits for your business. Let DeAir be your trusted partner in building the optimal animal feed preservation environment.

Contact DeAir now via hotline 0925 977 579 or visit our website deair.com.vn for consultation and the most suitable solution!

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)