Office & Factory: 442/8 National Highway 1A, An Phu Dong Ward, District 12, HCMC

Hotline: 0925 977 579

Email: deair@deair.com.vn

| SPECIFICATIONS | |

|

: (320 - 1,200) m3/h |

|

: (1.4 - 8.34) kg/h (20oC, 60%) |

|

: (2.676 - 11.84) kW |

|

: 220V/1 Ph /50Hz (DE-320 - DE-800) 380V/3 Ph/ 50Hz (DE-900 - DE-1200) |

Dezenno Rotor Dehumidifiers - Achieve humidity control below 30% for seed storage, laboratories, and warehouses

Dezenno rotor dehumidifiers are designed to precisely control both relative and absolute humidity, maintaining extremely low dew points in industries requiring stringent humidity control, such as pharmaceuticals, electronics, food processing, seed storage, and precision engineering.

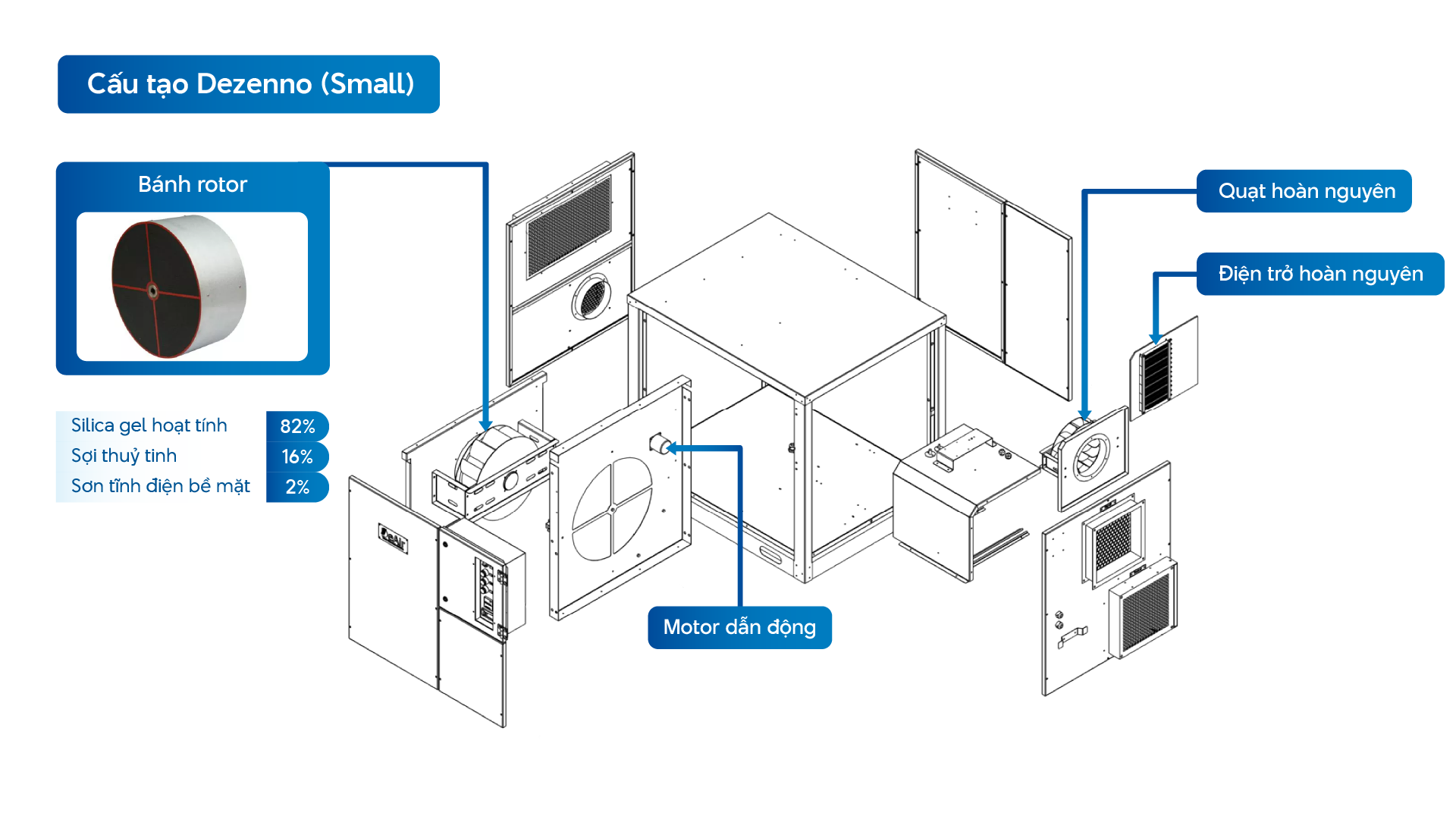

1. Structure

Dezenno rotor dehumidifiers are equipped with comprehensive connection ports for fresh air reactivation, humid air intake, dry air supply, and exhaust air, ensuring precise airflow control and continuous, uninterrupted dehumidification.

The key feature of these units is the honeycomb-structured desiccant rotor. It is constructed from alternating layers of flat and corrugated sheets, impregnated with a desiccant material, primarily active silica gel. This configuration allows a large number of axial air channels to run parallel through the structure, effectively drying the air as it passes through.

The dehumidification section also includes a reactivation chamber, reactivation fan, and drive motor, ensuring high performance and durability.

2. Operating principle

Dezenno rotor dehumidifiers utilise desiccant rotor technology to remove moisture from the air. Moist air is drawn into a section of the rotating rotor, where the desiccant material adsorbs the moisture. As the rotor turns, the moisture-laden desiccant is moved to the reactivation section. Simultaneously, outdoor air is heated by an electric heater and blown through the reactivation section. This hot air dries the desiccant, releasing the moisture into the exhaust airstream. Finally, the regenerated desiccant material returns to the dehumidification section to continue the cycle.

3. Applications of Dezenno Rotor Dehumidifiers

As a highly effective dehumidification solution, Dezenno rotor dehumidifiers are particularly suitable for environments requiring extremely low and precise humidity control, such as:

In addition to precise humidity control, effective condensation prevention, product protection, and enhanced productivity, Dezenno rotor dehumidifiers operate quietly, save energy, are durable, and easy to install and maintain. This provides exceptional cost-effectiveness and peace of mind for businesses.

4. Benefits of choosing DeAir

Dezenno Rotor Dehumidifiers - The optimal solution for humidity and condensation control for all businesses.

Office & Factory: 442/8 National Highway 1A, An Phu Dong Ward, District 12, HCMC

Hotline: 0925 977 579

Email: deair@deair.com.vn