- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU -

Industrial Electrical Cabinets & Automation Panels

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

Dezenno Industrial Dehumidifier: Precise & Durable Humidity Control Solution For Every Factory

07/05/2025

Denzeno Industrial Dehumidifier: The optimal humidity control solution for industrial environments in Vietnam, especially in hot and humid climates.

High humidity is a persistent challenge in industrial environments in Vietnam, especially in hot and humid climates such as the South. Humidity that is not effectively controlled can become a "silent enemy", causing serious consequences such as adversely affecting product quality, reducing production efficiency, disrupting processes and even threatening business profits. Faced with this problem, finding a reliable humidity control solution is essential.

In that context, the DeAir industrial dehumidifier series stands out as an advanced solution, specially designed to meet the most stringent requirements for humidity control in industrial environments.

Why Should Businesses Choose Dezenno Rotor Industrial Dehumidifiers?

In industrial humidity control, refrigerant dehumidifiers are quite popular, but rotor (or desiccant dehumidifier) technology offers superior power and flexibility, especially for applications requiring high precision. Dezenno industrial dehumidifiers use advanced rotor technology, which does not rely on the principle of refrigeration to condense water vapor.

This technology has important advantages that directly solve industrial humidity problems:

- Outstanding performance at low temperatures and extremely low humidity: Condensing dehumidifiers typically work best at room temperature and moderate relative humidity. Their performance drops significantly when the temperature or humidity drops. In contrast, Dezenno rotor dehumidifiers still operate efficiently even at low temperatures and are capable of achieving very low humidity levels, maintaining the required low dew point. This is important for industries that require cold dry environments or low absolute humidity.

- Continuous operation: Condensing dehumidifiers may need to stop for defrosting when operating at low temperatures. Thanks to the simultaneous dehumidification and regeneration processes, rotor dehumidifiers Dezenno can operate continuously without interruption.

- Durable in harsh environments: Industrial environments often have dust and sometimes mild chemicals. The structure of industrial rotor dehumidifiers like Dezenno is designed to be more durable to withstand these conditions better than condensing machines. Dezenno machines can also integrate suitable filtration systems to operate effectively in dusty environments such as fertilizer production.

- Precise humidity control: Dezenno is capable of accurately controlling both relative humidity (RH) and absolute humidity.

Compared to household rotor dehumidifiers, Dezenno industrial dehumidifiers are completely different in scale and performance. Household machines have small capacity, are only suitable for family spaces and are not durable enough to operate continuously 24/7 in harsh industrial environments. Dezenno is built with much larger capacity, durable design and precise control system to meet the strict needs of factories and warehouses.

Industrial Rotor Dehumidifier for Factories: Effective, Durable | DeAir

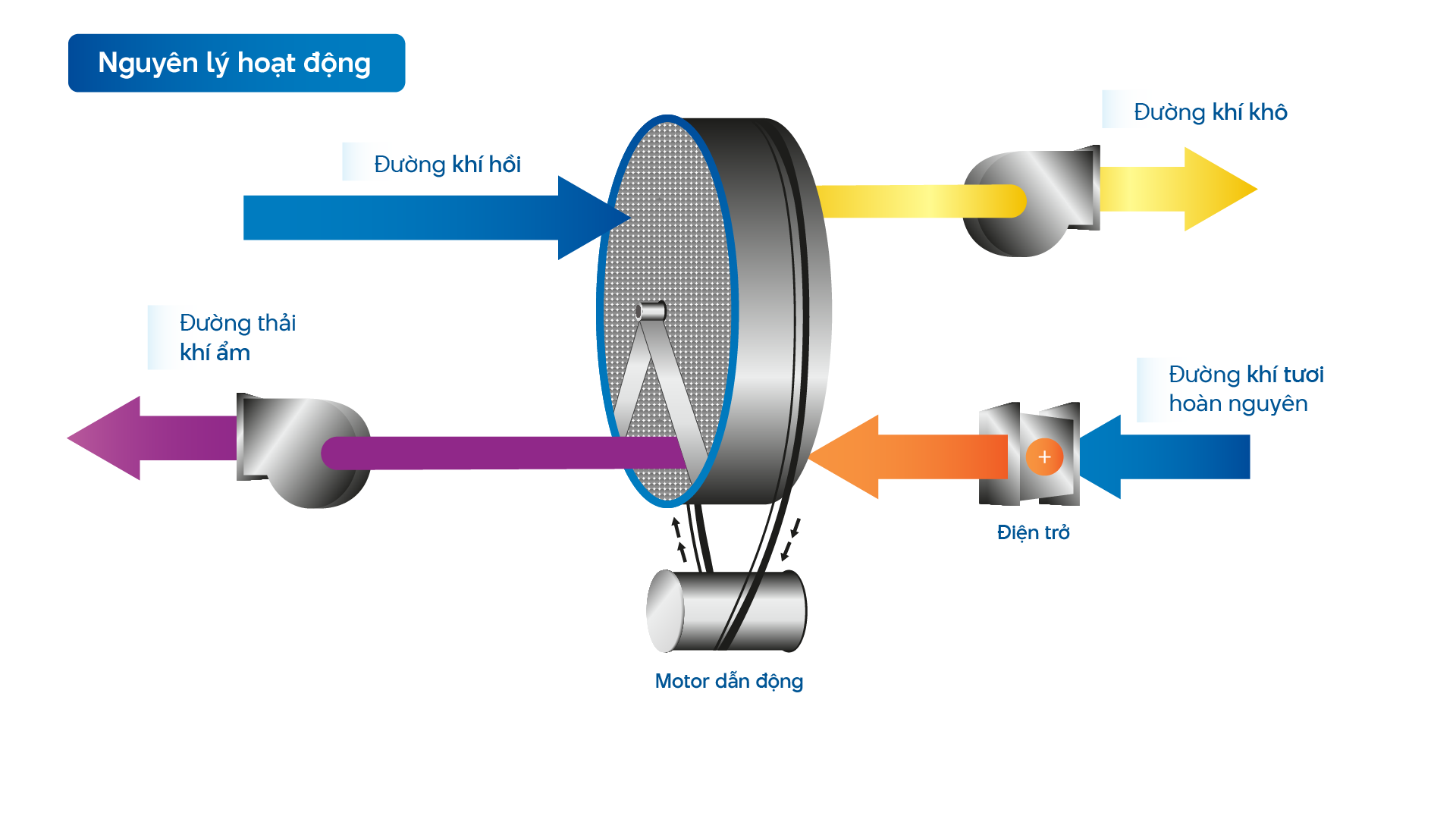

Discover the "Heart" of Technology: Structure and Operating Principle of Dezenno Rotor Dehumidifier

To better understand the outstanding capabilities of Dezenno industrial dehumidifier, let's find outu about its structure and operating principle.

Impressive structure: The Dezenno rotor dehumidification system is designed with scientific air connection ports, including:

- Moist air inlet: Leads air that needs to be treated for humidity from the target environment into the machine.

- Dry air outlet: Provides a flow of dehumidified air back to the area that needs to be controlled.

- Regeneration air inlet: Brings in a flow of hot air (usually heated fresh air) to regenerate the moisture absorption capacity of the material on the rotor.

- Regenerated moisture exhaust: Discharges the air stream carrying the removed moisture into the environment.

This air port design ensures that the air flow is tightly controlled and the dehumidification process is continuous and effective.

The central part, the "heart" of the system, is the dehumidifying rotor. This rotor has a special honeycomb structure, made of ceramic material with alternating layers and impregnated with high-quality desiccant, commonly activated silica gel or zeolite. The honeycomb structure creates thousands of parallel air channels, optimizing the contact area between humid air and the desiccant material, thereby improving the dehumidification efficiency.

In addition to the rotor wheel, the system also includes a regeneration box (where the desiccant is regenerated), an exhaust/blowing fan (ensuring air flow) and a rotor drive motor (helping the rotor rotate continuously).

Dezenno 300-1200 Rotor Dehumidifier - Precise Humidity Control

Dezenno 1500-18000 Rotor Dehumidifier - Precise Humidity Control

Intelligent operating principle (Continuous moisture adsorption)

The operating principle of the Dezenno rotor dehumidifier is based on the continuous moisture adsorption process when the rotor rotates through two main areas:

- Processing area (Air drying): Humid air from the area to be controlled is brought into the machine by the fan. Here, the air can pass through the primary evaporator to lower the temperature, increasing the dehumidification efficiency of the rotor. The air then passes through the rotor wheel, where the desiccant material absorbs the water vapor. The air exits this zone significantly drier. If a lower temperature is required, the dry air continues through the secondary evaporator to cool before being supplied back to the room.

- Regeneration Zone (Rotor Regeneration): The part of the rotor wheel that is saturated with moisture will rotate to the regeneration zone. Here, a stream of hot air (usually heated by a resistor to about 110°C or other heat source) is blown in the opposite direction through the rotor channels. The high temperature causes the water vapor to evaporate and be released from the desiccant material. The hot air carrying this moisture is then discharged outside.

The continuous rotation of the rotor ensures that these two stages take place in parallel and continuously, helping the device maintain a stable and continuous dehumidification capacity in the space to be controlled control.

Wide Applications of Dezenno Rotor Dehumidifiers:

Thanks to its extremely low humidity control and durable operation, Dezenno industrial rotor dehumidifiers are the ideal solution for many industries that require dry and tightly controlled environments. The Dezenno product line has a wide range of capacities, from small models (dehumidification capacity 1.4 - 8.34 kg/h at 20°C, 60% RH) to large models (dehumidification capacity 10.5 - 134.0 kg/h at 20°C, 60% RH, air flow up to 18000 m³/h). This enables Dezenno to meet most industrial needs, from small to large scale.

Typical applications include:

- Pharmaceuticals: Strict humidity control in the production of tablets, powders, packaging and storage areas of raw materials and finished productsto ensure quality, efficiency and prolong product life.

- Electronics: Maintain extremely low humidity in clean rooms for manufacturing semiconductor components and printed circuit boards (PCBs) to prevent static electricity, oxidation and ensure the quality of sensitive products.

- Food: Prevent clumping and mold for powdered and granulated products such as sugar, powdered milk, and cereals. Applications in low-temperature food drying to preserve nutrients and quality.

- Warehousing: Protects electronics, papers, documents, artwork, seeds, and other sensitive items from damage due to moisture and mold.

- Laboratory: Ensures stable humidity for environmentally sensitive experiments, chemical and specimen storage.

- Other industries: Including lithium-ion battery manufacturing (ensures performance, safety), paints and plastics (ensures surface quality), paper (prevents deformation), and even in recirculating aquaculture systems (RAS) to control air quality and prevent mold disease.

Special highlights: Dezenno industrial dehumidifier is an ideal solution for the fertilizer production industry, especially in the South of Vietnam. The hot and humid climate all year round, especially the rainy season, aggravates the problem of fertilizer clumping. Dezenno is capable of maintaining extremely low humidity in packaging and warehouse areas, effectively preventing moisture absorption and clumping. With strong moisture separation ability regardless of input temperature and humidity, Dezenno is the optimal solution for protecting fertilizers in long-term storage and sensitive production stages under these harsh climate conditions.

Industrial Rotor Dehumidifier for Factories: Effective, Durable | DeAir

Reference:

Outstanding Benefits When Choosing Dezenno Rotor Dehumidifier:

Investing in Dezenno industrial dehumidifier brings many practical benefits to businesses:

- Accurate and stable humidity control: Maintains a dry environment according to the requirements of the production or storage process, even at very low levels.

- Prevents condensation: Eliminates the risk of condensation causing product damage and equipment, which is extremely important in many industries.

- Protect and improve product quality: Extend shelf life, maintain physical and chemical properties of products.

- Improve production productivity: Minimize interruptions caused by moisture problems (such as system blockages in fertilizer production).

- Smooth operation and energy saving: Optimized design for dehumidification and regeneration performance, along with low noise during operation.

- High durability, easy installation and maintenance: Made from high quality materials and designed modularization, which increases the service life and facilitates operation and maintenance.

- Long-term cost-effectiveness: Although the initial investment cost may be higher than that of a condenser, the strict humidity control efficiency, durability and longevity in industrial environments provide superior long-term economic benefits.

Compare Energy-Saving Dehumidifiers: DeAir Heat Pump vs. Other Technologies | Expert Advice

Why Choose DeAir and Dezenno Rotor Dehumidifiers Today?

When choosing Dezenno industrial rotor dehumidifiers, you not only own a modern device but also cooperate with DeAir, a trusted partner, specializing in manufacturing dehumidifiers, AHUs and HVAC equipment in Vietnam.

Exclusive benefits when choosing DeAir include:

- Made in Vietnam: Dezenno products are designed and manufactured right in Vietnam. This helps DeAir be flexible in customizing products according to the specific requirements of each customer and conditions local climate, ensuring the most optimal solution.

- 24/7 professional technical service: DeAir's team of experienced, highly trained engineers and technicians are always ready to provide technical support whenever you need it, ensuring the system always operates stably.

- Comprehensive and periodic maintenance program: DeAir provides professional maintenance programs, helping equipment operate at optimal performance, prolonging its life and minimizing the risk of unexpected breakdowns.

- Comprehensive solutions: DeAir provides consulting services for solution design, drying industry solutions, and technical services.

With a commitment to quality, dedication and continuous improvement, DeAir always brings optimal value and prestige to customers.

Don't Hesitate! Protect Your Products and Optimize Your Production Today!

If your business is facing humidity challenges in the pharmaceutical, electronics, food, warehouse, or especially fertilizer production industries in Southern Vietnam, DeAir's Dezenno industrial rotor dehumidifier is the superior and necessary solution.

Let DeAir accompany you to build the most optimal humidity control solution for your business. Contact us now to receive a quote and professional support from DeAir's team of experts.

Contact information Contact:

- Hotline: 0925 977 579

- Office & Factory: 442/8 National Highway 1A, An Phu Dong Ward, District 12, Ho Chi Minh City

- Contact DeAir: Address, Map, Hotline & Quick Contact Form

We look forward to working with you to ensure the most efficient production and storage environment!

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)