- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU -

Industrial Electrical Cabinets & Automation Panels

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

Energy-Saving Dehumidifier Comparison: Heat Pump DeAir vs. Cold Condenser & Adsorption Rotor Technology

21/04/2025

DeAir Energy-Saving Heat Pump Dehumidifier: Superior Performance Solution for Industrial Applications

Effective humidity control with optimal operating costs is always a top priority in industries. This article delves into DeAir's advanced Heat Pump dehumidifier technology, a solution that delivers superior dehumidification performance and impressive energy savings, and compares it to traditional dehumidification technologies.

High air humidity has always been a major challenge for many industries in Vietnam, causing serious problems such as mold, equipment corrosion, affecting product quality and labor productivity. Dehumidifiers have become an effective solution to control humidity, providing a dry, comfortable space and playing a key role in maintaining an ideal working environment. However, one of the top concerns of consumers when choosing a dehumidifier is the ability to save energy.

Why Energy-saving Dehumidifiers Based on Heat Pump Technology Are the Best Choice Vietnamese?

Choosing a dehumidifier is not just about controlling humidity but also about economic efficiency and sustainability. Energy-saving dehumidifiers, especially those using Heat Pump technology, bring the following benefits:

- Reducing energy costs: This is the core advantage. Heat Pump technology allows the machine to achieve a significantly higher coefficient of performance (COP) than traditional cold condensing dehumidifiers, which means less energy is consumed to remove the same amount of moisture.

- Temperature stability: Unlike cold condensing machines that blow out cold, dry air, Heat Pump machines use the heat from the condensing process to warm the dry air before returning it to the space. This helps maintain room temperature stability, which is especially important in temperature-sensitive industrial processes.

- Durable operation and long life: Heat Pump systems are often designed with high-quality components and intelligent control systems, contributing to improved reliability and longer machine life.

- Reduced environmental impact: More efficient use of energy means reduced carbon emissions, in line with the trend of sustainable development.

Heat Pump Technology in Vacuum Cleaners DeAir Humidity: Advanced Humidity Control Solution

DeAir is a reputable company specializing in the production of dehumidifiers, AHU (Air Handling Unit) and HVAC (Heating, Ventilation, and Air Conditioning) equipment in Vietnam. With a focus on energy efficiency, DeAir has pioneered the application of Heat Pump technology in its industrial dehumidifier lines.

Heat Pump technology is a breakthrough in the field of humidity control, providing a solution that is energy-saving and high dehumidification efficiency. Unlike traditional cold condensing dehumidifiers, heat pumps use the heat released during the condensation process to heat the dry air before blowing it out, helping to minimize changes in room temperature and significantly save electricity costs. Heat pump dehumidifiers combine the principle of moisture condensation with the heat pump cycle.

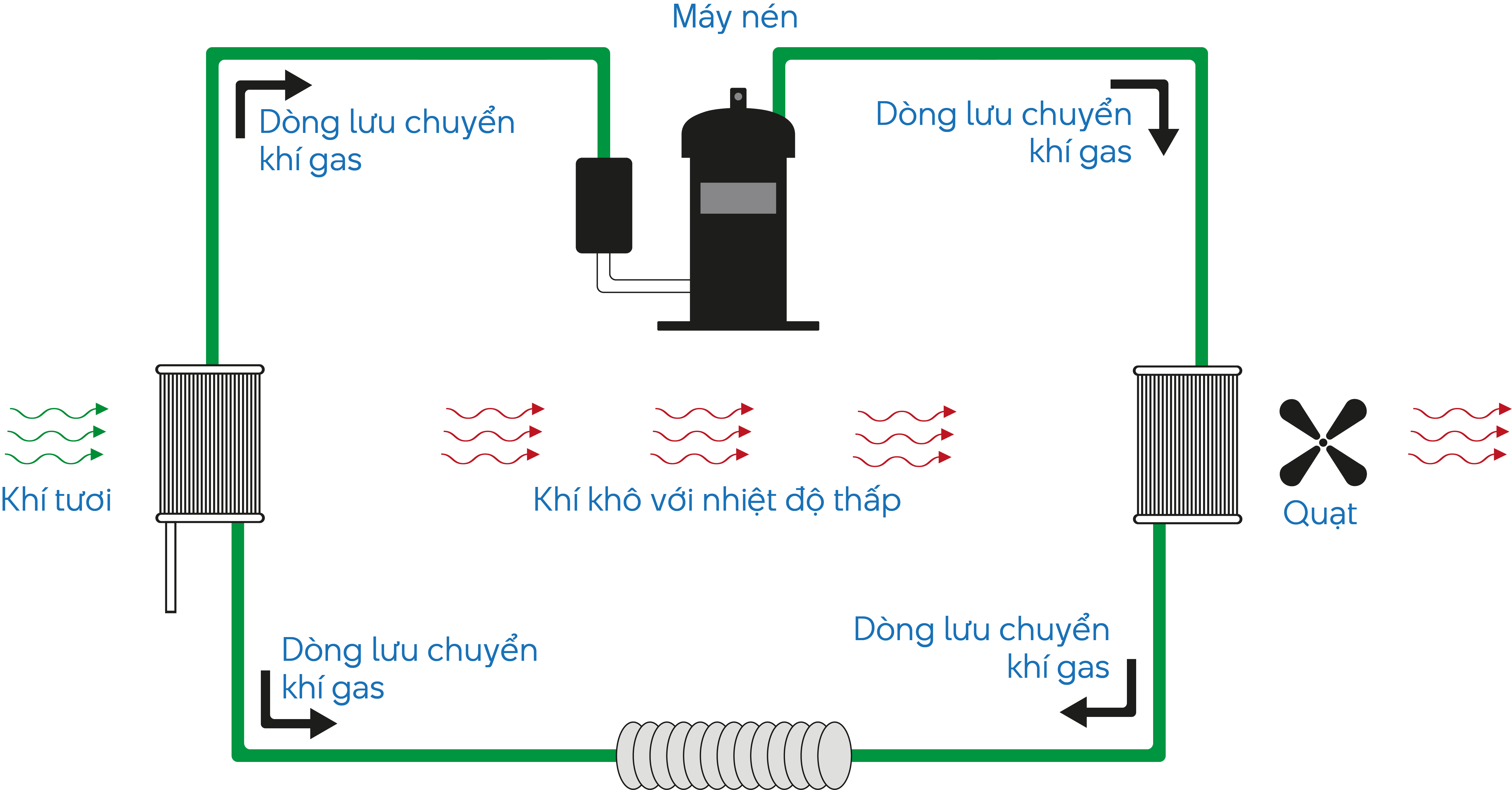

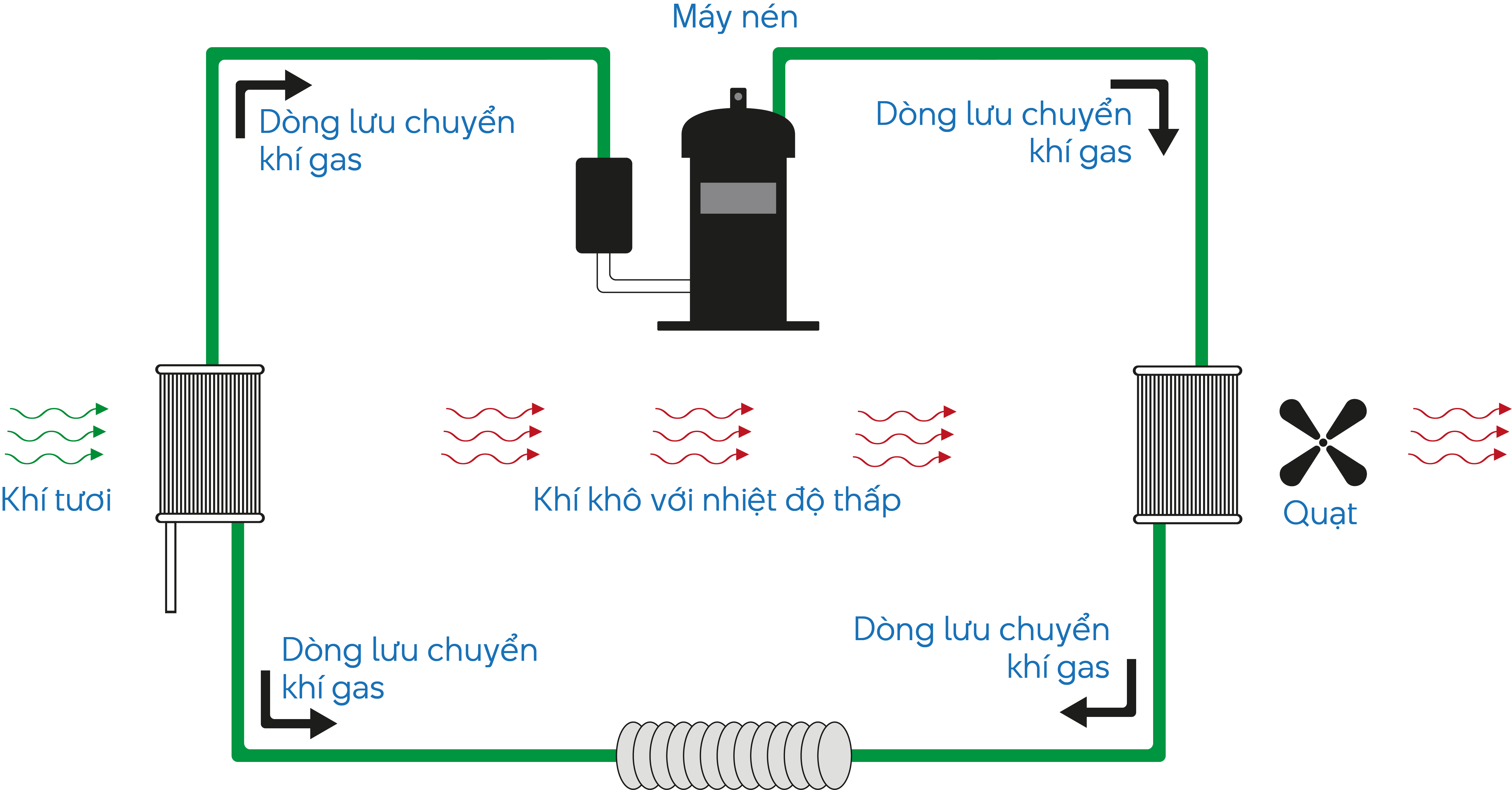

Basic operating principle of Heat Pump dehumidifiers:

Heat Pump dehumidifiers combine the principle of moisture condensation with the heat pump cycle. The refrigerant, usually R410A with an ODP (Ozone Depletion Potential) of 0, circulates in a system.closed system. The dehumidification process takes place as follows:

- Damp air suction: Humid air from the environment is sucked into the machine by the fan and passes through the evaporator.

- Damp condensation: At the evaporator, the refrigerant at low pressure and low temperature absorbs heat from the humid air, causing the air temperature to drop below the dew point. The moisture in the air condenses into water and is collected.

- Dry air heating: The air after being dehumidified (drier and colder) continues to pass through the condenser. Here, the high-pressure, high-temperature refrigerant releases heat, heating this dry air.

- Blowing dry and warm air back: The dry and warm air is blown back into the space, helping to maintain a more stable humidity and temperature.

Heat pump cycle:

This cycle includes four main stages of the refrigerant:

- Compression: The refrigerant in the form of low-pressure vapor is compressed by the compressor to high pressure and high temperature.

- Condensation: The refrigerant in the form of high-pressure vapor releases heat at the condenser, converting into a high-pressure liquid. This heat is used to heat dry air.

- Expansion: The high-pressure liquid refrigerant passes through the expansion valve, reducing the pressure and temperature.

- Evaporation: The low-pressure liquid refrigerant absorbs heat from the humid air at the evaporator, converts it into low-pressure vapor, and the cycle repeats.

DeAir offers a wide range of industrial Heat Pump dehumidifiers, including:

- Heat-Pump DeAir.RE Dehumidifier

- Heat-Pump DeAir DeAir.RE-H

- Heat-Pump DeAir.RE-INOX Dehumidifier (stainless steel shell, suitable for harsh environments)

- Heat-Pump DeAir.CRE Isothermal Dehumidifier (simultaneous control of temperature and humidity)

- DeAir.RE-CL Ceiling Mounted Dehumidifier (saving installation space)

These series are designed to meet the humidity control needs for many different industrial applications, from production rooms, warehouses to commercial areas. In particular, the model Heat-Pump DeAir.RE-300 Dehumidifier has a power consumption of only 4.6kW for a dehumidification capacity of up to 300 liters/day, showing impressive energy saving capabilities. The Coefficient of Performance (COP) of heat pumps is often higher than that of cold condensers, showing the ratio between dehumidification energy and energy consumption.

Compare Heat Pump DeAir Dehumidifier with Other Dehumidifiers

To better understand the advantages of Heat Pump DeAir dehumidifier, let's compare it with other popular dehumidification technologies on the market:

1. Refrigerant Dehumidifier

- Operating principle: Suck humid air into the machine, pass it through a cooling coil to lower the temperature. The moisture in the air condenses into water and is stored in a tank or discharged through an exhaust pipe. The air after passing through the cooling coil will be drier and blown back into the room.

- Advantages: Initial investment costs are usually lower, easy to maintain, effective in temperatures from 15°C to 30°C.

- Disadvantages: Performance is significantly reduced at low temperatures (below 15°C), power consumption can be higher than a heat pump to remove the same amount of moisture, blowing out drier and colder air, causing discomfort.

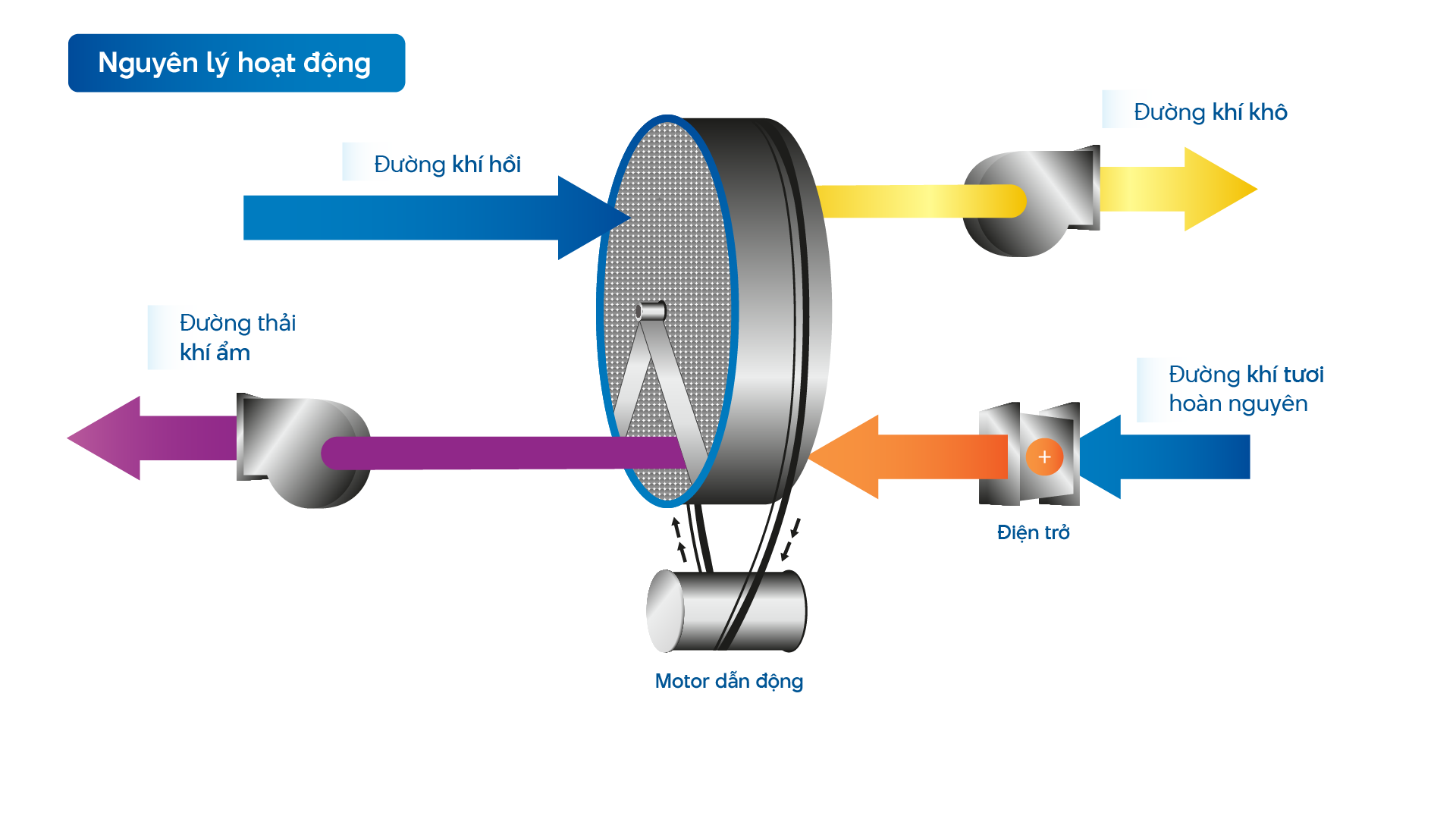

2. Rotor Adsorption Dehumidifier (Desiccant/Rotor Dehumidifier)

- Working principle: Use adsorbent (usually Silica gel) on a rotor to absorb moisture from the air. As the rotor rotates, part of it passes through the regeneration zone, where hot air is blown through to remove moisture and regenerate the adsorbent.

- Advantages: Effective operation at low temperatures (even below 0°C), Ability to control humidity accurately at very low levels (even below 40% RH).

- Disadvantages: Operating costs are usually higher due to the need for energy to heat the regeneration air stream (usually by a thermistor), the structure is more complex, requiring careful maintenance. Under average temperature and humidity conditions, cold condensing dehumidifiers typically consume less electricity than rotor dehumidifiers with the same dehumidifying capacity.

3. DeAir Heat Pump Dehumidifier

- Operating principle: Combining the principle of moisture condensation with the heat pump cycle, taking advantage of the heat released from the condensation process to heat the dehumidified air. The refrigerant in the heat pump system undergoes a compression and condensation cycle in the condenser.

- Advantages: Outstanding energy efficiency, consuming significantly less energy (30-50% or more) than a cold condenser to remove the same amount of moisture, only maintain more stable performance at low temperatures, returning dry but warmer air, helping to maintain temperature stability in the space.

- Disadvantages: The initial investment cost may be higher than that of a cold condenser.

Thus, DeAir's Heat Pump dehumidifier stands out with its outstanding energy saving ability, while still ensuring high dehumidification efficiency and stable operation in many environmental conditions, especially in industrial applications.

Outstanding Technologies Contributing to Energy Saving of Heat Pump DeAir Dehumidifiers

Heat Pump DeAir dehumidifiers are often equipped with advanced technologies to optimize performance and durability:

- Advanced Heat Pump technology: Effectively utilize heat pump cycle, which helps the machine achieve high dehumidification efficiency with low energy consumption. DeAir is proud to manufacture, design, install and maintain energy-saving heat pump dehumidification solutions.

- Wide operating temperature range: Models can operate effectively in a variety of temperature conditions, suitable for the diverse climate in Vietnam.

- Intelligent control system: Integrating modern electronic controllers, allowing accurate humidity setting and monitoring. Proper hysteresis settings (the range of humidity fluctuations allowed before the machine automatically switches on/off again) also help save energy.

- High-quality materials: Use durable, corrosion-resistant materials to ensure longevity and reliability of the machine in harsh industrial environments (e.g. powder-coated steel or stainless steel housing).

- Optimized design: The machine design is optimized in terms of aerodynamics, which increases airflow and dehumidification efficiency.

- Additional integration options: Some models can be customized with additional features such as air filtration systems, remote control connection feature.

DeAir uses R410A gas in many heat pump dehumidifiers, providing high cooling and heating efficiency and no ozone depletion (ODP = 0).

Applications of DeAir Energy-Saving Dehumidifier

With its powerful performance and energy saving capabilities, DeAir Heat Pump dehumidifier is an ideal choice for many industrial applications such as:

- Production room: Maintain stable humidity, protect raw materials and machinery.

- Warehouse: Prevent mold, damage to goods, ensure product quality meets export standards.

- Commercial area: Control humidity, preserve fresh food.

- Special industries such as pharmaceuticals, electronics, agricultural product preservation.

To ensure operating efficiency and energy saving, it is very important to choose a machine with the right capacity (proper sizing) for the area and volume of the space.

Conclusion

Energy-saving dehumidifiers are a smart and sustainable solution for your humidity control needs. With advanced Heat Pump technology, DeAir dehumidifiers provide outstanding energy efficiency, helping you reduce operating costs and contribute to environmental protection. Compared to other technologies such as cold condensation and adsorption rotors, DeAir's Heat Pumps demonstrate a clear advantage in energy saving, especially in industrial applications that require high efficiency and stable operation.

Reference Source Reference:

- ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): The leading organization for standards and knowledge in the field of HVAC&R (Heating, Ventilation, Air Conditioning and Refrigeration). ASHRAE standards and publications are a reliable and in-depth source of information.

See more:

Dehumidifier: Optimal Solution for Living Space and Production in Vietnam

Daxwell: Industrial Heat Pump DryerAdvanced Industry, Cost Optimization

Large Capacity Dehumidifier For Factories, Warehouses: DeAir Heat Pump

If you are looking for an energy-saving dehumidifier solution for your business, contact DeAir immediately for advice and to choose the most suitable product!

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)