- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

DeAir Technical Story: When "Precision" Is The Measure Of Dedication

07/01/2026

The Person Who Breathes Life Into Dezenno Machines

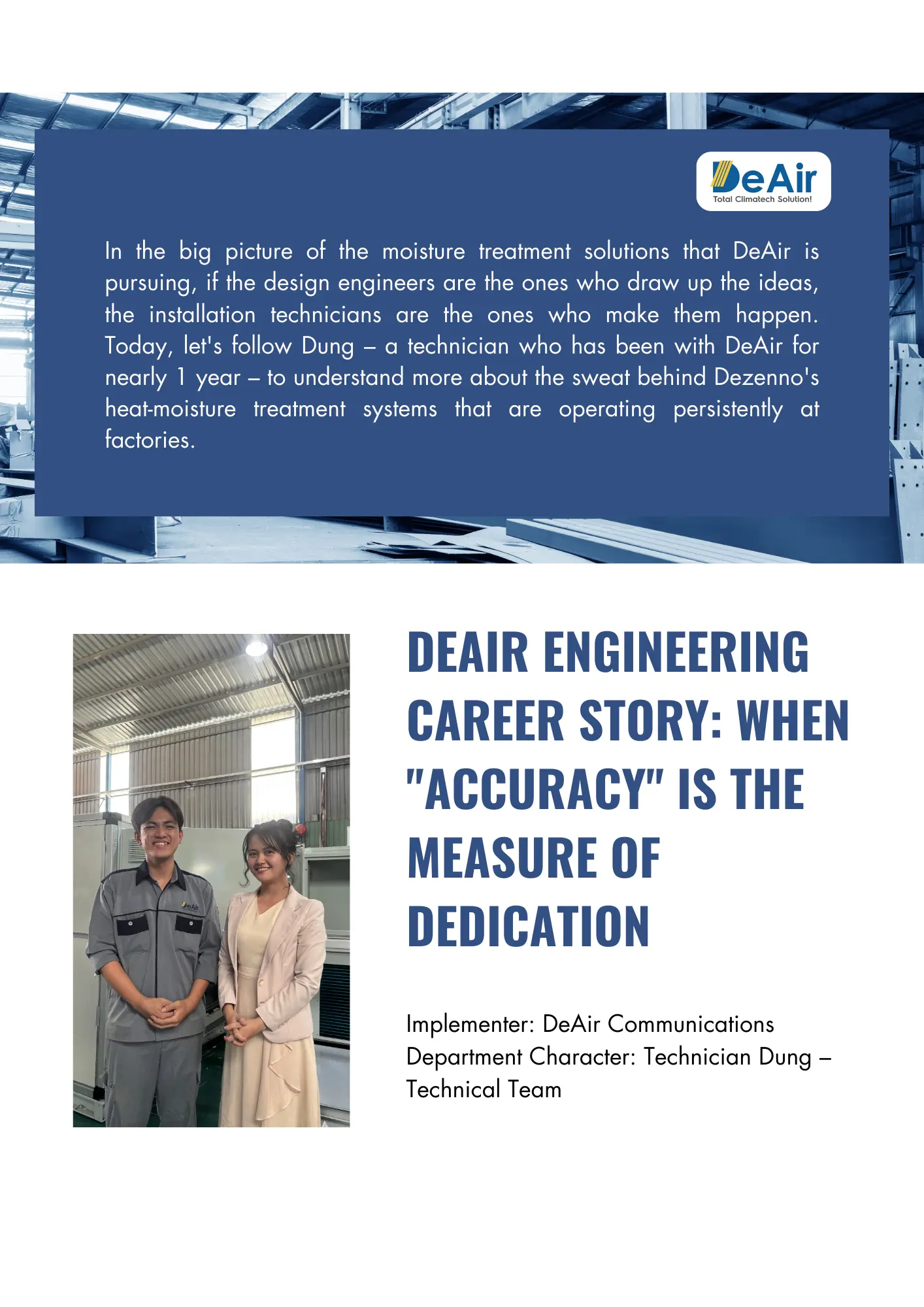

In the grand picture of humidity control solutions that DeAir pursues, if design engineers are the ones who sketch the ideas, then installation technicians are the ones who turn them into reality.

Today, let's follow Dung – A Technician from the DeAir Technical Team (who has been with us for nearly 1 year) – to better understand the sweat and effort behind the Dezenno heat and humidity treatment systems operating durably in factories across Vietnam.

"Contrary to many people's thoughts that technical work is just 'manual labor', a DeAir technician's workday always begins with meticulous calculation."

1. A Day Starts with Drawings, Not Screwdrivers

Sharing with the Media Team, Dung said that the standard workflow of a professional technician is not to rush into installing the machine immediately.

“My working day usually starts with checking the site, reviewing drawings, and preparing tools. Only then do I proceed with installation and step-by-step checking...” – Dung shared.

Reviewing HVAC drawings and equipment schematic diagrams is a vital step. For industrial dehumidifiers and dryers, a deviation in machine placement or duct direction of just a few centimeters can affect the Static Pressure (Pa) and reduce the humidity treatment efficiency of the entire system.

2. "Alignment" – The Measure of Dedication

When asked about the most difficult point in the construction process, Dung did not hesitate to point out the key factor that DeAir Technical Service always commits to customers: Optimization.

“The hardest part is the alignment and connection of the system to fit the actual site conditions. If it is not done correctly from the beginning, the machine will still run, but the efficiency will not be optimal, and problems will easily arise later.”

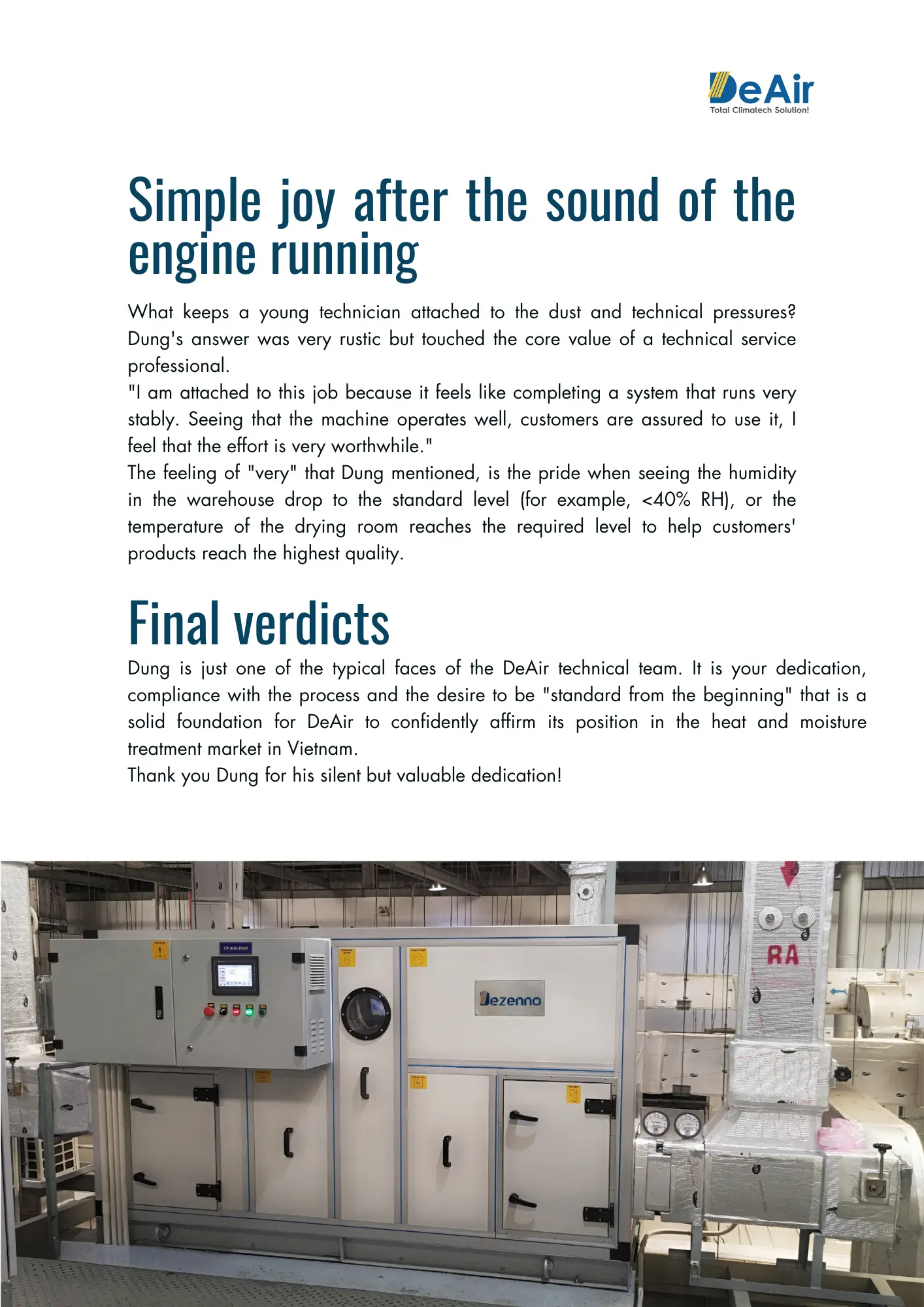

As industry experts, we clearly understand Dung's point. A high-end Dezenno dehumidifier, if not correctly adjusted for Fresh Air flow, Return Air flow, and Dew Point temperature, will waste energy uselessly. Dung's meticulousness is the first layer of protection helping customers save on long-term operating costs.

3. Speed Comes with Quality

Despite strict technical requirements, progress is always a pressure at factory sites, pharmaceutical warehouses, or textile plants.

Dung stated: “For a standard dehumidifier or dryer installation shift, it usually takes about half a day to 1 day. The time may vary depending on the installation location, duct system, and actual conditions...”

However, for complex systems such as central dehumidification systems, this process can last up to 15 days to ensure all parameters meet standards before handover (FAT/SAT). This is the "golden" time to turn a silent machine into the heart of the entire environmental control system.

4. Simple Joy After the Machine Runs

What keeps a young technician attached to dusty construction sites and technical pressures? Dung's answer is very rustic but touches the core value of a service professional:

“I stick with this job because the feeling of completing a stably running system is very satisfying. Seeing the machine operate well and the customer using it with peace of mind makes me feel my effort is worth it.”

The "very satisfying" feeling Dung mentioned is the pride of seeing the humidity in a medicine warehouse drop to standard levels (e.g., < 40% RH), or the drying room temperature reaching the required level to help the customer's products achieve the highest quality.

Dung is just one of the typical faces of the DeAir technical team. It is your dedication, adherence to procedures, and desire to "do it right the first time" that are the solid foundation for DeAir to confidently affirm its position in the heat and humidity treatment market in Vietnam.

Thank you, Dung, for your silent but valuable contribution!

Need Technical Support? Contact DeAir Now!

Dedicated technicians like Dung are always ready to serve 24/7.

DEAIR JOINT STOCK COMPANY

📞 Hotline: +84 933 628 660 (Ms. Hong)

📧 Email: deair@deair.com.vn

🌐 Website: deair.com.vn

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)