- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU -

Industrial Electrical Cabinets & Automation Panels

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

Choose the energy-saving industrial dehumidifier that best suits your business

05/05/2025

Energy-Saving Industrial Dehumidifiers: The Optimal Solution for Vietnamese Enterprises

In the context of increasing energy costs and green manufacturing requirements, choosing an energy-efficient humidity control solution is extremely important for industries in Vietnam. High air humidity is a major challenge, causing mold, equipment corrosion, affecting product quality and productivity. Industrial dehumidifier is an effective solution, but the question is how to both control humidity effectively and save electricity significantly?

This article will introduce in detail the leading energy-saving industrial dehumidifier technologies today, especially Heat Pump Dehumidifier DeAir and Dezenno Rotor Dehumidifier, helps you understand the operating principles and choose the most suitable solution for your needs.

Energy Saving in Industrial Dehumidification: Why is it a Mandatory Trend?

Optimizing the power consumption of dehumidification systems helps businesses reduce operating costs and improve competitiveness. This is especially important in the context of Vietnam's tropical monsoon climate, where humidity control occurs almost year-round. Energy savings must go hand in hand with ensuring dehumidification performance, especially in industrial environments that require strict humidity control.

Advanced technologies such as Heat Pump and Adsorption Rotor are leading this trend, providing a balance between efficiency and energy costs.

Heat Pump Technology: Smart Energy Reuse

Heat pump dehumidifiers are a breakthrough in humidity control technology. Unlike traditional cold condensing dehumidifiers, heat pumps utilize the heat released during condensation to heat the dry air before blowing it out. This helps to minimize room temperature changes and significantly save on electricity costs. This technology achieves a significantly higher coefficient of performance (COP), which means less energy is consumed to remove the same amount of moisture.

Operating principle of the Dehumidifier DeAir Heat Pump Dehumidifier:

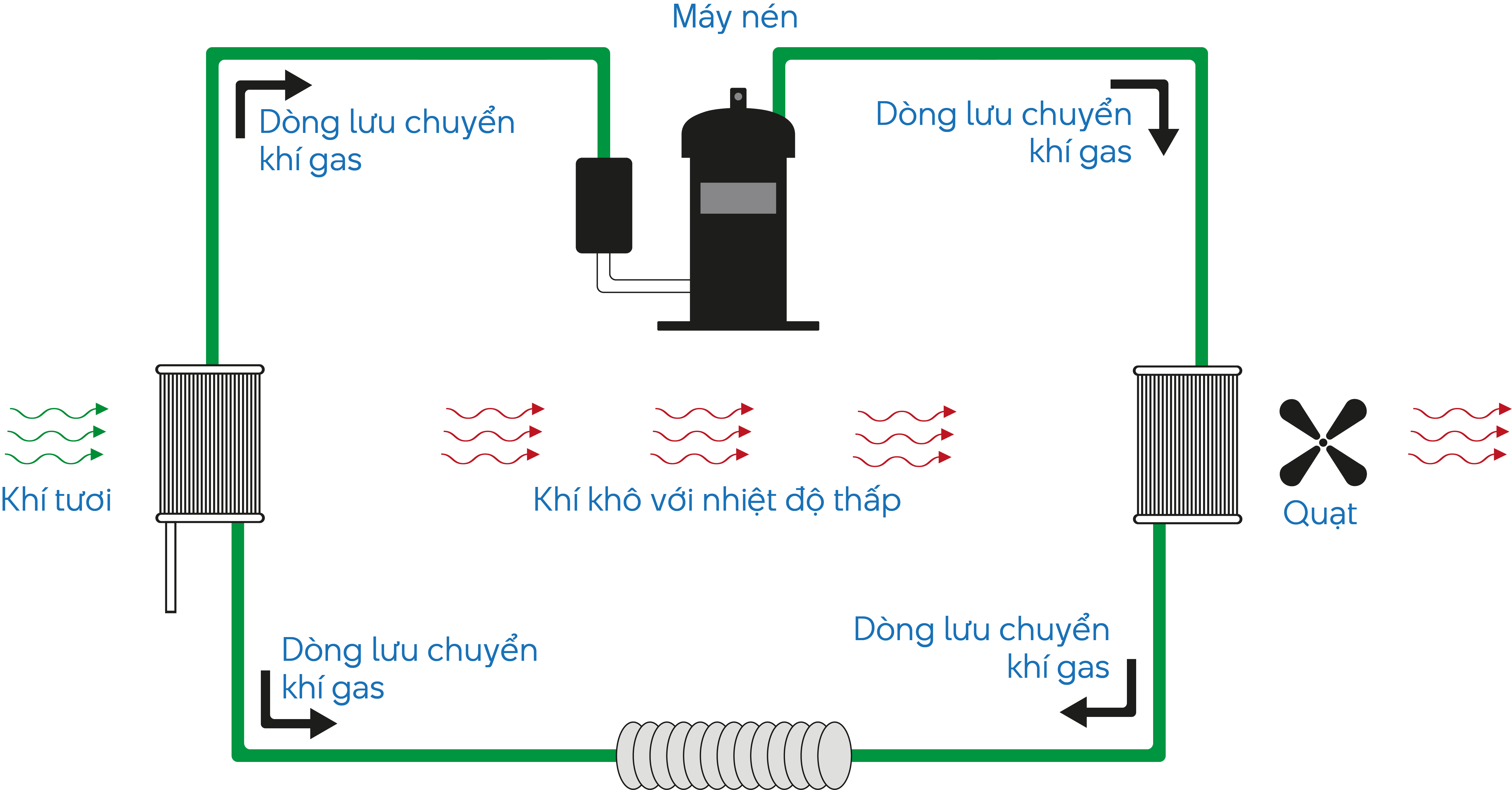

The DeAir heat pump dehumidifier combines the principle of moisture condensation with the heat pump cycle to achieve optimal dehumidification efficiency. This cycle includes the following main steps:

- Damp air extraction: The exhaust fan draws humid air from the environment into the machine.

- Cooling and condensing: Humid air passes through the evaporator, where the refrigerant at low pressure and temperature absorbs heat. The air temperature drops below the dew point, causing the water vapor to condense into water and be collected. This condensation process also releases heat.

- Heat Utilization (Heat Pump): The heat released from the condensation process is absorbed by the refrigerant in the heat pump system. The refrigerant then goes through a compression (compressor), condensation (condenser) cycle in the condenser (which is arranged to exchange heat with dry air).

- Heating dry air: The dehumidified air (drier and colder) passes through the condenser, absorbing heat from the refrigerant, becoming warmer.

- Blowing dry and warm air out: The fan pushes dry and warm air back into the room, helping to maintain the desired humidity without feeling too cold and keeping the temperature stable.

The basic heat pump cycle includes a compressor, condenser, expansion valve and evaporator. DeAir uses R410A gas in many heat pump dehumidifiers, providing high cooling and heating efficiency and no ozone depletion (ODP = 0), while being popular and safe.

Phaseout of Class II Ozone-Depleting Substances | US EPA

Advantages of DeAir Heat Pump Dehumidifier:

-

Outstanding energy efficiency: Consumes significantly less energy (can be 30-50% or more) than a refrigerant condenser to remove the same amount of moisture, helping to reduce operating costs.

- Good low temperature performance: Maintains more stable performance than a cold condenser in low temperature environments.

- Minimizes impact on room temperature: Returns dry but warmer air, maintaining temperature stability, important in sensitive applications.

- Application versatility: Effective in many industrial environments (warehouses, clean rooms, manufacturing).

- High durability: Systems are often designed with high quality components.

DeAir offers a wide range of industrial heat pump dehumidifier, including DeAir.RE, DeAir.RE-H, DeAir.RE-INOX (stainless steel housing for harsh environments), DeAir.CRE (isothermal, simultaneous control of temperature and humidity), and DeAir.RE-CL (ceiling mounted, space saving). These machines are equipped with advanced Heat Pump technology, wide operating temperature range, intelligent control system, high-quality materials and optimized airflow design to ensure performance and durability.

Adsorption Rotor Technology (Dezenno by DeAir): Precise Humidity Control at Extremely Low Levels

Different from the cooling principle, rotor dehumidifiers use special dehumidifying material (usually activated silica gel) impregnated on a rotor with a honeycomb structure. This machine operates effectively even at low temperatures and is capable of achieving extremely low humidity levels (low dew points), which is difficult for condensing machines.

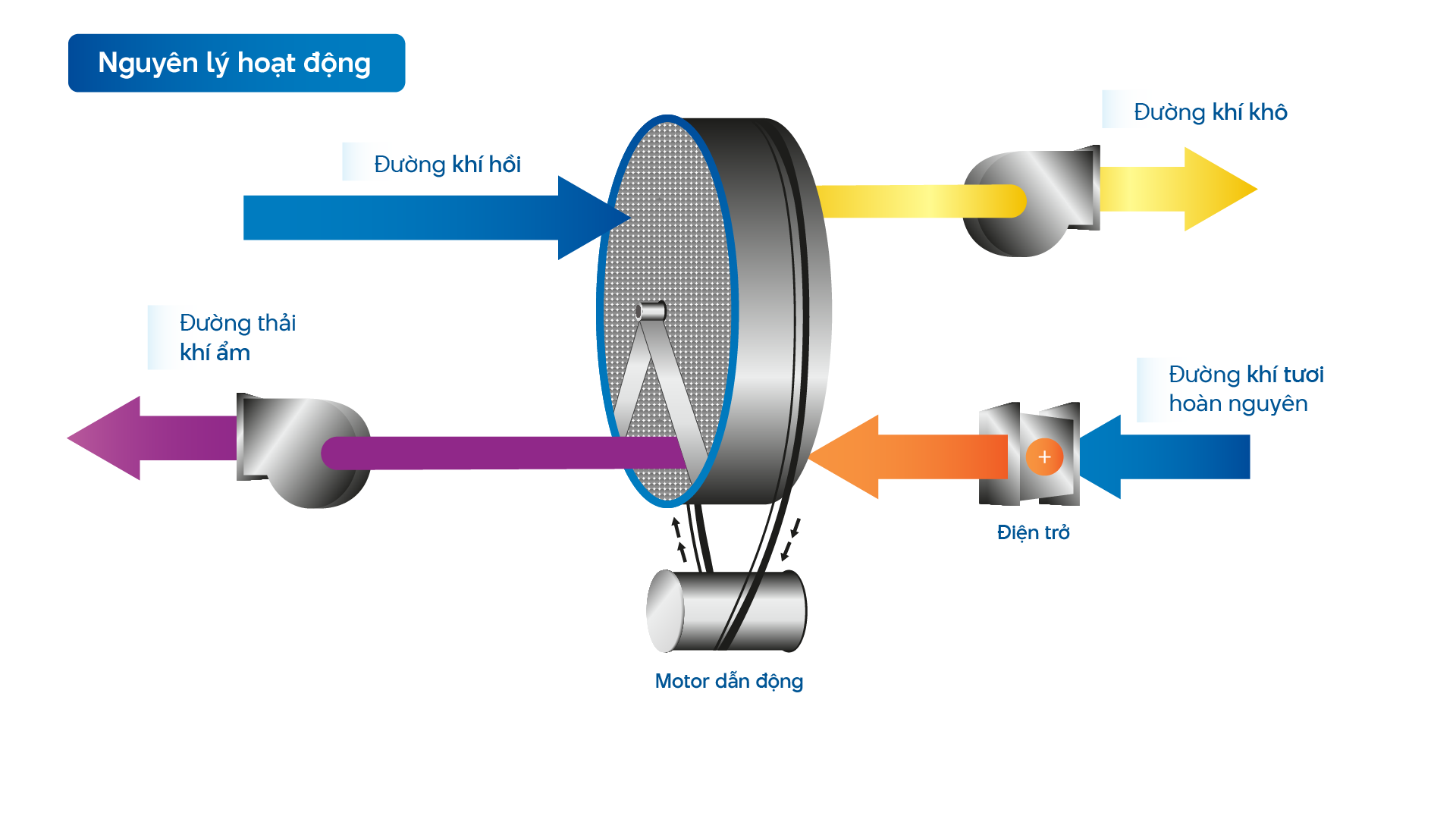

Operating principle of Dezenno Rotor Dehumidifier:

The operating principle is based on the process of continuous moisture absorption. The dehumidifying rotor rotates slowly through two separate zones:

- Processing zone: Humid air from the area to be dried is drawn through the rotor by the fan. The dehumidifying material on the rotor absorbs water vapor, making the air drier when it is released. The honeycomb structure creates many parallel air channels, optimizing the contact area.

- Regeneration zone: The part of the rotor that has absorbed moisture moves to this zone. Here, a stream of hot air (usually heated by an electric resistor or other heat source) is blown through thea rotor in the opposite direction. The high temperature evaporates the absorbed water vapor, and this moist air is discharged.

The continuous rotation of the rotor ensures the system's non-stop dehumidification ability.

Dezenno, a brand of DeAir, provides dehumidifiers Industrial humidifiers use rotor technology, designed to ensure stable dehumidification performance under harsh conditions and optimize energy during rotor regeneration. Dezenno is capable of precise control of both relative humidity (RH) and absolute humidity, preventing condensation. Dezenno series machines have various capacities, from 1.4 kg/h to 134 kg/h or more.

Advantages of Dezenno Rotor Dehumidifier:

-

Effective at low temperature and humidity: Works well even below 10°C or 0°C and when humidity is very low.

- Achieve extremely low humidity levels: Capable of precise humidity control, reaching levels below 40% RH.

- Continuous operation: The dehumidification and regeneration processes take place in parallel, without stopping to defrost like a low-temperature condenser.

- Durable in harsh environments: Dust-resistant design, suitable for industrial environments.

- Precise humidity control: Maintain a stable humidity environment according to strict requirements.

Industrial rotor dehumidifiers like Dezenno are significantly different from residential rotor dehumidifiers in terms of capacity, durability and control features, built for the scale and requirements of the business.

Comparing Industrial Dehumidifiers: Heat Pump vs. Cold Condensing vs. Rotor Adsorption

Choosing the right type of energy-saving industrial dehumidifier depends on the current environmental conditions, target humidity requirements, initial investment budget and operating costs.

-

Refrigerant Dehumidifier:

- Origin Reason: Lowers air temperature to allow water vapor to condense.

- Advantages: Initial investment costs are usually lower, easy to maintain. Effective in room temperature (~15-30°C) and average humidity (~45-60%).

- Disadvantages: Efficiency drops significantly at low temperatures (below 15°C). Electricity consumption may be higher than Heat Pump to remove the same amount of moisture. Blows out drier and colder air, which can be uncomfortable.

-

Desiccant/Rotor Dehumidifier - Dezenno by DeAir:

- Principle: Adsorbs moisture with desiccant material on the rotor, then regenerates with hot air.

- Advantages: Works effectively at low temperatures (even below 0°C). Ability to control humidity accurately at very low levels (below 40% RH). Continuous operation. Durable in harsh environments.

- Disadvantages: Operating costs are usually higher due to the energy required to heat the regenerated air stream (usually by a thermistor). More complex structure. Initial investment costs are often higher than condensing units.

-

Heat Pump Dehumidifier (Heat Pump) - DeAir Heat Pump:

- Principle: Combines moisture condensation with a heat pump cycle to reuse heat.

- Advantages: Outstanding energy efficiency, consumes less energy than icesignificant. Significant energy savings compared to condensing and usually rotor for the same humidity at average conditions. Maintains more stable performance at lower temperatures than condensing. Returns dry but warmer air, helping to maintain a stable room temperature.

- Disadvantages: Initial investment costs may be higher than for cold condensing units.

- See more:

- Compare Energy-Saving Dehumidifiers: DeAir Heat Pump vs. Other Technologies | Expert Advice

When Should You Use Which Type of Dehumidifier?

Based on your needs and environmental conditions, you can choose as follows:

- Prioritize energy saving, relatively stable temperature environment: You should prioritize DeAir's Heat Pump dehumidifier lines. This technology significantly reduces long-term energy costs thanks to its high efficiency.

- Deep dehumidification needs, low humidity and temperature environments (e.g. below 10°C) or extremely low humidity requirements (below 40% RH, low dew point): The Rotor Dehumidifiers Dezenno (by DeAir) series are the optimal choice. The rotor ensures dehumidification performance even in harsh conditions where condensing units cannot meet the requirements. Typical applications include pharmaceutical, electronics, food, special storage (seeds, equipment), laboratories, and especially fertilizer production in Southern Vietnam where the year-round hot and humid climate can easily cause clumping.

- General needs, moderate humidity control (above 45% RH) under room temperature conditions (above 15°C) and limited initial investment budget: Condensing dehumidifiers can be an economical initial choice. However, it is necessary to consider the higher operating costs compared to Heat Pump and the reduced efficiency when the temperature or humidity is low.

- DeAir currently provides all of the above solutions, please contact us immediately for detailed advice on specific solutions for your production, work and storage activities.

- Contact DeAir: Address, Map, Hotline & Quick Contact Form

Other Technologies Contribute to Energy Saving:

In addition to choosing the basic technology (Heat Pump, Rotor, Condenser), the energy saving efficiency of industrial dehumidifiers also depends on design and control factors:

- Smart control and sensor system: Using precise humidity sensors, advanced controllers (PID, algorithms) to flexibly adjust capacity, timer function and scheduling operations to help the machine run only when needed, optimizing energy. Setting the hysteresis (allowable humidity fluctuation range) appropriately also helps save electricity.

- Optimizing the airflow design and using high-efficiency fans: Reducing air resistance and using high-efficiency fans help reduce the power consumption of the fan unit, applicable to all types of dehumidifiers.

- Using high-efficiency compressors (especially Inverter): Inverter compressors have the ability to flexibly adjust capacity according to demand, helping to save electricity compared to fixed compressors. This is an important factor to consider when choosing a condensing dehumidifier or Heat Pump.

Why Choose DeAir for Energy-Saving Industrial Dehumidification Solutions?

DeAir is a reputable company specializing in the production of dehumidifiers, AHUs, and HVAC equipment in Vietnam. DeAir is committed to providing comprehensive industrial dehumidification solutions, meeting a variety of needs.

- Made in Vietnam: Products such as the Heat Pump dehumidifier and the Dezenno Rotor line are designed and manufactured in Vietnam. This allows DeAir to flexibly customize products according to each customer's specific requirements and local climate conditions, while optimizing performance and costs.

- Focus on energy efficiency: DeAir pioneers the application of Heat Pump technology and optimizes Rotor technology to provide energy-saving solutions.

- 24/7 professional technical service: A team of experienced engineers is ready to provide technical support, ensuring stable system operation.

- Regular maintenance program: Helps extend the life of the equipment and maintain optimal performance.

Where to buy energy-saving industrial dehumidifiers

Choosing an energy-saving industrial dehumidifier is a key factor for businesses in Vietnam to optimize operating costs and improve production efficiency in a hot and humid climate. Heat Pump and Adsorption Rotor technology offer superior advantages over traditional condensers, especially in applications requiring high efficiency and stable operation in a variety of environmental conditions.

DeAir's Heat Pump dehumidifier stands out with its outstanding energy-saving ability and maintains temperature stability. Meanwhile, the Dezenno Rotor Dehumidifier is an indispensable solution for environments that require extremely low humidity and operate efficiently at low temperatures.

By carefully analyzing the specific needs of environmental conditions, humidity requirements and budget, businesses can choose the most suitable technology and machine line from DeAir to achieve the optimal balance between dehumidification performance and energy savings.

Don't miss the opportunity to own an advanced and energy-saving humidity control solution from DeAir. Contact DeAir today for detailed advice and a quote for the most suitable energy-saving industrial dehumidifier solution for your business!.

Contact information

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)