- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

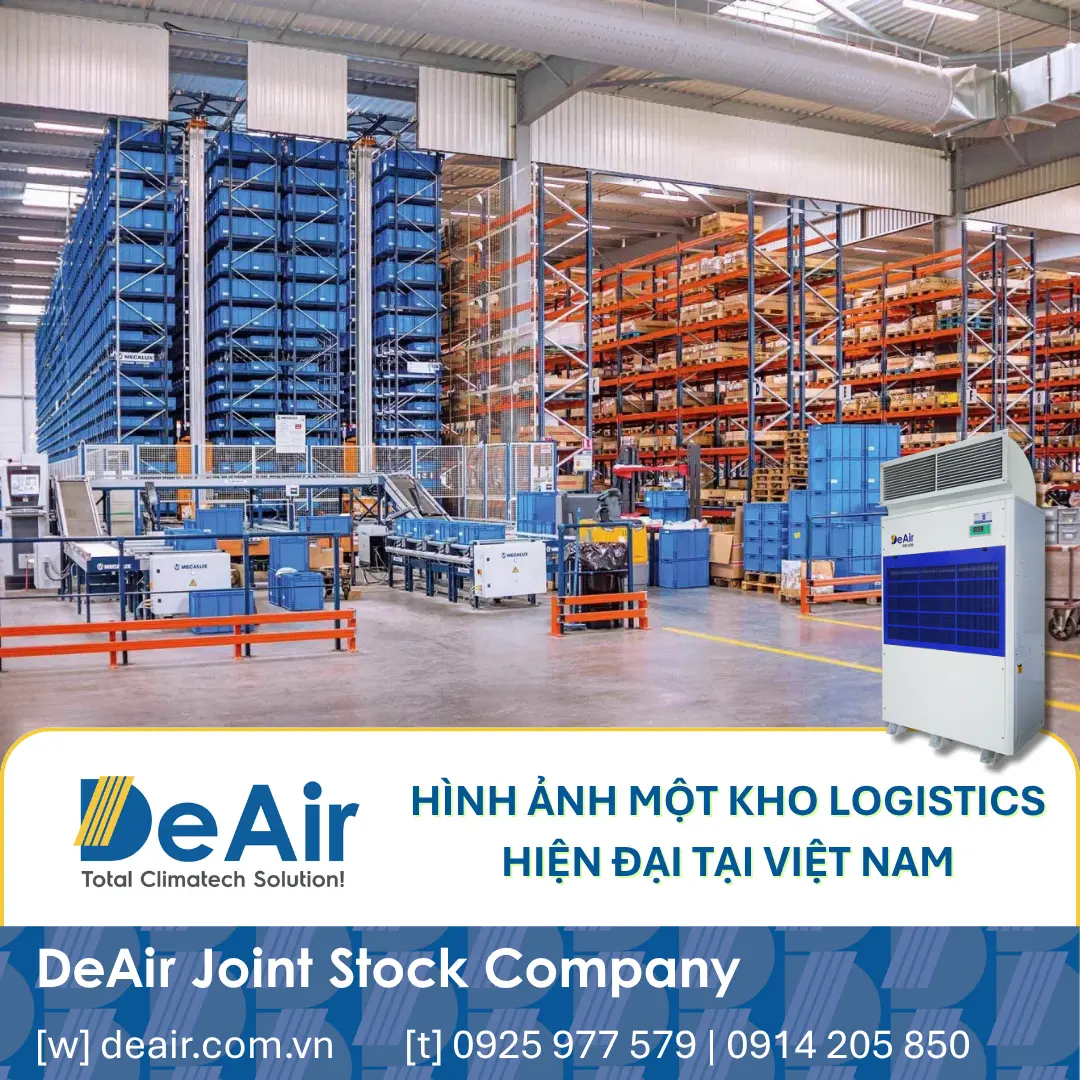

Sustainable Logistics Starts in the Warehouse: The Optimal Humidity Control Solution

29/10/2025

Sustainable Logistics Starts in the Warehouse: Optimization Through Humidity Control

According to the National Statistics Office, Vietnam is proactively developing a roadmap for transitioning to sustainable logistics. This is not just about "green transport" but also includes optimizing warehouse operations to minimize waste and enhance supply chain efficiency.

However, within the supply chain, warehouses harbor significant risks leading to losses and waste. One of the most insidious yet dangerous culprits is uncontrolled humidity. This article will analyze the critical role of warehouse humidity control as a pillar of sustainability and introduce the optimal technological solution from DeAir.

Table of Contents

- 1. Uncontrolled Humidity: The Massive "Hidden Cost" in Logistics Warehouses

- 2. Humidity Control: A Pillar for Sustainable & Efficient Logistics Warehouses

- 3. Why Are Industrial Dehumidifiers the Optimal Solution?

- 4. DeAir - Partnering with Vietnam's Logistics Businesses on the Sustainable Path

- 5. Frequently Asked Questions (FAQ)

1. Uncontrolled Humidity: The Massive "Hidden Cost" in Logistics Warehouses

High humidity not only causes discomfort but directly destroys product value and impacts the sustainability of the supply chain.

Direct Losses Due to Product Damage

Almost every type of goods stored in logistics warehouses is sensitive to moisture:

- Electronics, Components: Corrosion, rust on pins and PCBs, leading to short circuits and failure.

- Garments, Footwear, Furniture: Mold growth, yellowing, musty odors, loss of aesthetic value, failing export standards.

- Dry Foods, Agricultural Products: Clumping (sugar, powder), loss of crispness (snacks, biscuits), germination (grains), insect infestation.

- Pharmaceuticals, Cosmetics: Alteration of active ingredients, reduced efficacy, changes in product texture.

- Paper, Cardboard Packaging: Softening, tearing, loss of protective function, difficulties in handling and transport.

- Metals, Machinery, Spare Parts: Severe rusting, reduced lifespan and reliability.

Indirect Losses Affecting Sustainability

These damages lead to significant resource waste, contradicting sustainable logistics goals:

- Resource Waste: Damaged goods that must be discarded represent a waste of all raw materials, production energy, transportation costs, etc.

- Increased Operational Costs: Costs arise from handling defective goods, repackaging, compensating customers, and damaging brand reputation.

- Poor Working Environment: Affects warehouse workers' respiratory health, risk of slipping on damp floors.

2. Humidity Control: A Pillar for Sustainable & Efficient Logistics Warehouses

According to the Council of Supply Chain Management Professionals (CSCMP), sustainable logistics involves minimizing environmental impact and optimizing economic efficiency. Proactive humidity control using industrial dehumidifiers directly contributes to both goals:

- Waste Reduction: Protecting goods = Reducing the amount of damaged inventory that needs disposal, saving resources and lessening environmental burden.

- Resource Efficiency: Avoids waste from repackaging. Better preservation extends product shelf life.

- Operational Efficiency: Goods are always ready for dispatch. Dry, sturdy packaging makes loading, unloading, and transport safer and faster, reducing accident risks.

- Improved Working Conditions: A drier, cleaner, and safer environment for warehouse staff.

3. Why Are Industrial Dehumidifiers the Optimal Solution?

Passive methods like natural ventilation are weather-dependent and uncontrollable. Using desiccants is only effective for very small spaces and incurs high ongoing replacement costs. Industrial dehumidifiers offer the only proactive and sustainable control solution:

- Proactive & Precise Control: Maintains stable humidity at the desired setpoint (typically 50-60%RH), regardless of external conditions, as recommended by ASHRAE guidelines for storing various materials.

- High Capacity, Effective for Large Spaces: Meets the demands of modern large-scale logistics warehouses covering thousands of square meters.

- Automatic, Continuous 24/7 Operation: Ensures uninterrupted protection for goods.

DeAir.RE Heat-Pump Technology - The Choice for Modern Logistics

The DeAir.RE Heat-Pump dehumidifier series is a top choice for logistics warehouses due to:

- Energy Savings: Heat-Pump technology significantly reduces operating electricity costs, aligning with "sustainability" criteria.

- High Durability: Robust construction, quality components, and anti-corrosion coils suitable for warehouse environments.

- Smart Features: Continuous drainage, user-friendly digital controls, and the ability to connect to BMS (Building Management System) for remote monitoring and control.

4. DeAir - Partnering with Vietnam's Logistics Businesses on the Sustainable Path

DeAir understands the climatic challenges and specific requirements of the logistics industry in Vietnam. We offer more than just equipment; we provide comprehensive solutions:

- Free Consultation & Site Survey: Our experienced engineers will visit your site, assess the conditions, and recommend the most suitable solution.

- Diverse Solutions: We offer a full range from DeAir.RE (Heat-Pump), Olmas (Imported), to Dezenno (Rotor) for specialized warehouses.

- "Made in Vietnam" Advantage: Ensures clear origin, quality, and fast, reliable technical support directly from the manufacturer.

5. Frequently Asked Questions (FAQ)

1. What is the ideal humidity level for a logistics warehouse?

The ideal level depends on the type of goods stored. However, general recommendations from experts suggest maintaining the relative humidity (RH) between 50-60% is a safe range to prevent mold growth and minimize corrosion risks for most common goods.

2. How do I choose the right dehumidifier capacity for my warehouse?

Calculating the required capacity involves many factors like warehouse volume, insulation, temperature, target humidity, inventory, and traffic frequency. The best approach is to contact DeAir's technical team for a free site survey and consultation to ensure the correct capacity is chosen, avoiding waste or ineffectiveness.

3. Are Heat-Pump dehumidifiers really more energy-efficient than others?

Yes. Heat-Pump technology reuses the heat generated during the cooling process to warm the dry outlet air. This significantly reduces energy consumption compared to standard condensing dehumidifiers (which waste this heat) or drying methods using electric heaters, contributing to energy saving and sustainable logistics goals.

Don't Let Humidity "Corrode" Your Profits & Sustainability Goals!

Contact DeAir today for a free warehouse survey and consultation on the optimal humidity control solution, contributing to your company's sustainable logistics roadmap.

DEAIR JOINT STOCK COMPANY

Email: operation@deair.com.vn

Hotline: +84 925 977 579 (Ms. Tam) | +84 914 205 850 (Ms. Hoa)

Website: deair.com.vn

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)