- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

"Checking In" at Pho Anh Hai 10 Dan Phuong: Discussing the Secret to Drying Rice Noodles (Bun, Pho, Hu Tieu) for Perfect Quality and Export

03/11/2025

"Checking In" at Pho Anh Hai 10 Dan Phuong & The Story of Elevating Vietnamese Rice Noodles

Recently, the Vietnamese online community has been buzzing with the trend of "checking in" at "Pho Anh Hai - 10 Dan Phuong, Hanoi" – a fictional in-game location that has suddenly become famous in real life. While it's a humorous trend, it shows just how much love Vietnamese people have for the traditional dish of pho.

However, beyond the steaming hot bowl of pho, another "version" of pho, bun, and hu tieu noodles is increasingly dominating the market: the dried form, which serves the needs of long-term storage and export. This is no longer a story of entertainment, but a serious technological challenge. What is the secret to drying these rice noodles so that after boiling, they are still as chewy and delicious as fresh noodles, without breaking, turning sour, or being contaminated? The solution is certainly not the risky method of manual sun-drying.

Table of Contents

- 1. Manual Sun-Drying: The "Bottleneck" of the Dried Noodle Craft

- 2. The Mistake of High-Heat Drying: Why Do Noodles Break & Turn Mushy?

- 3. The Optimal Solution: Daxwell Heat-Pump Drying - Preserving Texture, Elevating Quality

- 4. Smart PLC & HMI Control: The "Soul" of a Perfect Drying Batch

- 5. DeAir "Made in Vietnam" - A Partner to Traditional Craft Villages

- 6. Frequently Asked Questions (FAQ)

1. Manual Sun-Drying: The "Bottleneck" of the Dried Noodle Craft

The method of drying noodles on bamboo racks outdoors has existed for hundreds of years, but it reveals fatal limitations in the modern industrial era:

- Weather & Time Risk: The process takes 1-2 days and is completely dependent on the sun. Rain or high humidity can cause the noodles to turn sour, ferment, or grow mold, leading to the loss of an entire batch.

- Food Safety Risk: Outdoor drying cannot avoid fine dust (PM2.5), insects (flies, bugs), etc. This makes the product unable to meet hygiene standards (like HACCP, ISO 22000) for export or modern distribution channels.

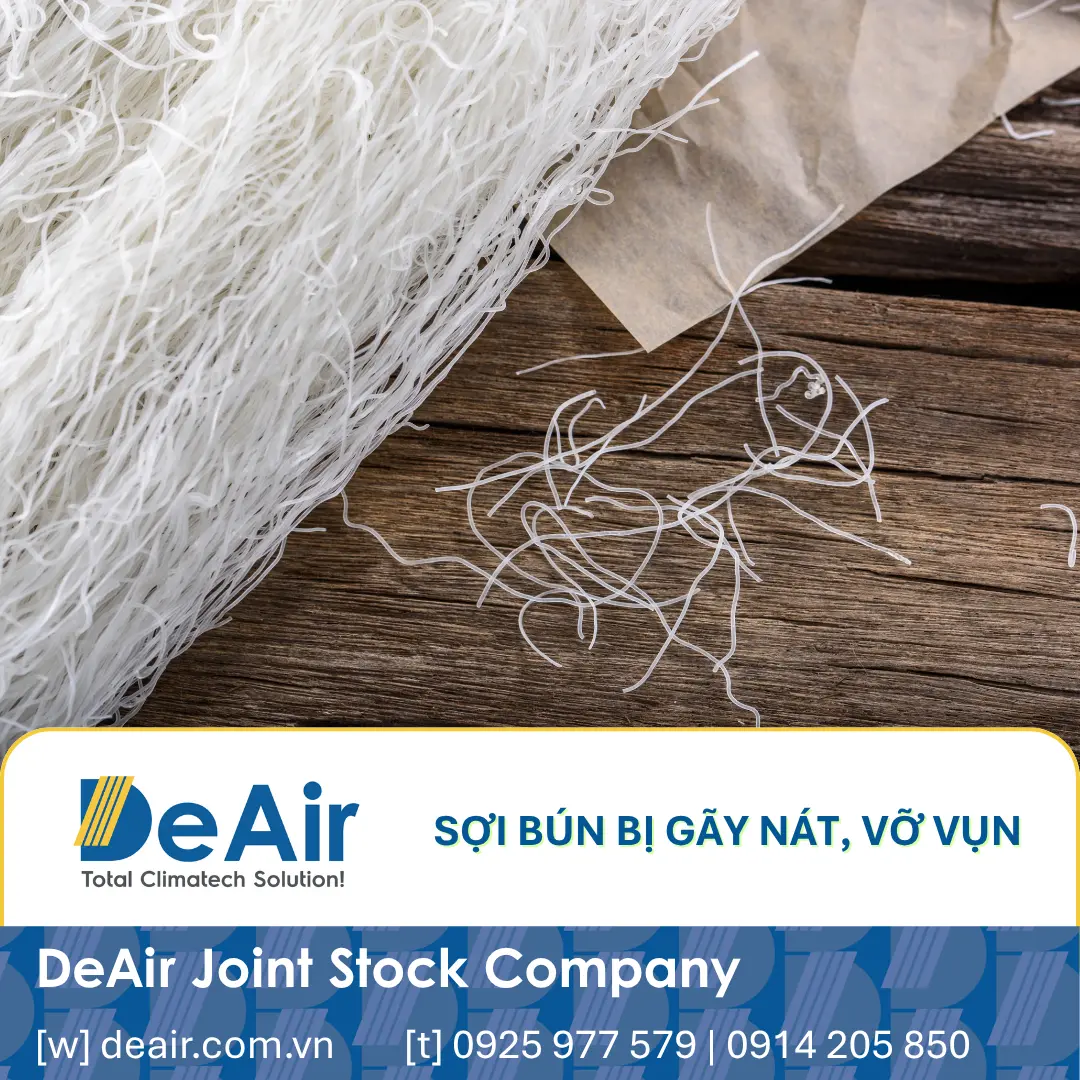

- Product Quality Risk: Strong sun dries the noodles too quickly, making the outer layer brittle while the core remains damp ("case hardening"). This leads to easy breakage during transport (increasing loss rates) and vulnerability to moisture regain after packaging.

2. The Mistake of High-Heat Drying: Why Do Noodles Break & Turn Mushy?

To overcome weather dependency, many facilities switch to electric resistance ovens or traditional kilns. However, drying at high temperatures (above 60°C - 70°C) causes another serious problem.

The main component of rice noodles is starch. According to food science research, when starch is exposed to high heat and moisture, it undergoes "gelatinization" (i.e., it "cooks") too quickly, and the noodle's structure is broken down.

The Result: The dried noodles look fine but are very brittle and break easily. Most importantly, when the consumer boils them, the noodles turn mushy and fall apart, losing their desired chewy texture.

3. The Optimal Solution: Daxwell Heat-Pump Drying - Preserving Texture, Elevating Quality

To maintain the starch structure, noodles must be dried at a low to medium temperature range (around 30°C - 55°C) to allow water to evaporate slowly. This is precisely where the Daxwell Heat-Pump technology shines.

- Low-Temperature Control: Daxwell's heat-pump drying technology operates perfectly in the 30-55°C range, allowing the noodles to dry slowly, thus preserving the starch structure.

- Quality Preservation: The final product, when boiled, remains chewy, translucent, and as delicious as fresh noodles.

- Superior Energy Savings: The heat-pump technology recycles heat energy, saving 50-70% on electricity costs compared to resistance heaters.

- Perfectly Clean, 24/7 Control: Drying takes place in a sealed (Panel) chamber, providing complete control over production regardless of rain or humidity, and meeting food safety standards for export.

4. Smart PLC & HMI Control: The "Soul" of a Perfect Drying Batch

Drying noodles doesn't just require one temperature. The process needs a "smart schedule" with multiple stages (e.g., stage 1 to dry the surface, stage 2 for deep moisture removal, stage 3 to "rest" and let core moisture escape...).

The Daxwell dryer is equipped with a PLC controller and HMI screen, allowing DeAir technicians and clients to precisely program these multi-stage drying cycles, ensuring every batch has the same consistent high quality.

5. DeAir "Made in Vietnam" - A Partner to Traditional Craft Villages

We don't just sell an "as-is" imported machine. We understand the unique characteristics of Vietnamese rice noodles. As a local manufacturer, DeAir has its own lab and has conducted extensive R&D to optimize the drying process. We are ready to run free drying tests on our clients' samples to find the best possible cycle for their specific product.

6. Frequently Asked Questions (FAQ)

1. How long does it take to dry noodles with a Daxwell dryer?

It's much faster than sun-drying. Depending on the noodle thickness and initial moisture, a complete drying cycle with a Daxwell Heat-Pump dryer typically takes only 6 to 10 hours, compared to 1-2 days of sun exposure.

2. Can the Daxwell dryer be used for other agricultural products?

Absolutely. The Daxwell Heat-Pump Dryer is designed for multi-purpose use, widely applied for drying fruits, vegetables, herbs, seafood, and other crafts like rattan and incense.

3. Why not just use a cheaper electric resistance dryer?

The initial investment for a resistance dryer might be lower, but the operating cost (electricity bill) will be 2-3 times higher than a Heat-Pump system. More importantly, the high, hard-to-control temperature of a resistance dryer can easily damage, break, and reduce the quality of the rice noodles.

Don't Let the Weather Dictate Your Productivity!

From "Pho Anh Hai 10 Dan Phuong" to traditional craft villages, it's time to elevate your dried bun, pho, and hu tieu products. Contact DeAir today for a consultation on the Daxwell drying solution and ask about our free sample drying test!

DEAIR JOINT STOCK COMPANY

Email: operation@deair.com.vn

Hotline: +84 925 977 579 (Ms. Tam) | +84 914 205 850 (Ms. Hoa)

Website: deair.com.vn

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)