- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU -

Industrial Electrical Cabinets & Automation Panels

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

Learn about the operating principle of the Dezenno Rotor dehumidifier

20/02/2025

Rotor Humidity Treatment Equipment Operating Principle: Superior Humidity Control Solution

In the modern industrial era, environmental humidity control plays a vital role in many industries, from pharmaceutical production, electronic components, to food and agricultural product preservation. Inappropriate air humidity can have serious consequences on product quality, reduce shelf life and affect work performance. That is why humidity treatment equipment is increasingly widely used, and rotor wheel dehumidification technology has emerged as an advanced solution.

Rotor humidity treatment technology: A step forward in industrial humidity control

Currently, there are two popular humidity treatment technologies: using refrigerant and dehumidifying technology using desiccant materials (Desiccant), typically the rotor wheel. The Dezenno rotor dehumidifier pioneers the application of Desiccant technology, designed to precisely control both relative humidity and absolute humidity, maintaining an extremely low dew point. This meets the strict requirements of industries such as pharmaceuticals, electronics, food, seed storage and precision engineering, where understanding the operating principle of the Rotor dehumidifier is extremely important.

Explore the structure of the Dezenno Rotor dehumidifier

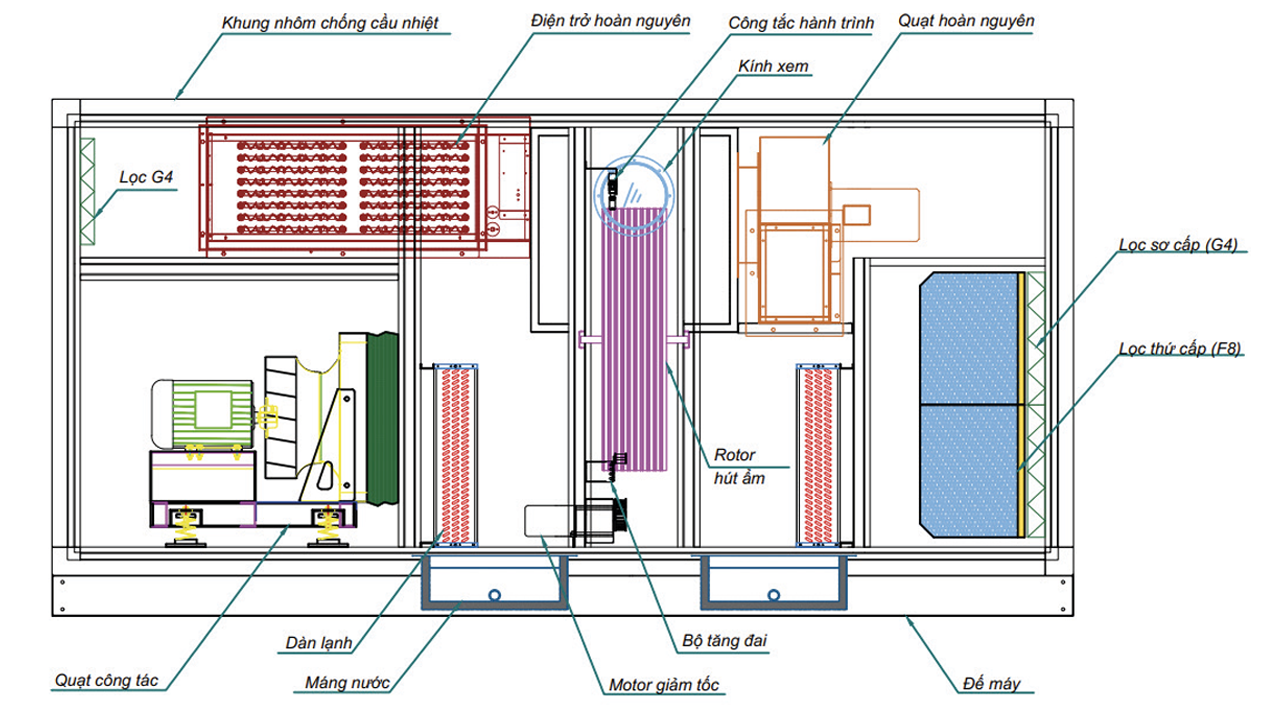

Structural diagram of the Dezenno rotor humidifier

The Dezenno rotor humidifier is intelligently designed with all the important connection ports: fresh regenerated air line, humid air input line, dry air output line and humid exhaust line. This port system ensures a continuous and tightly controlled air flow, optimizing the efficiency of the dehumidification process based on the operating principle of the Rotor dehumidifier.

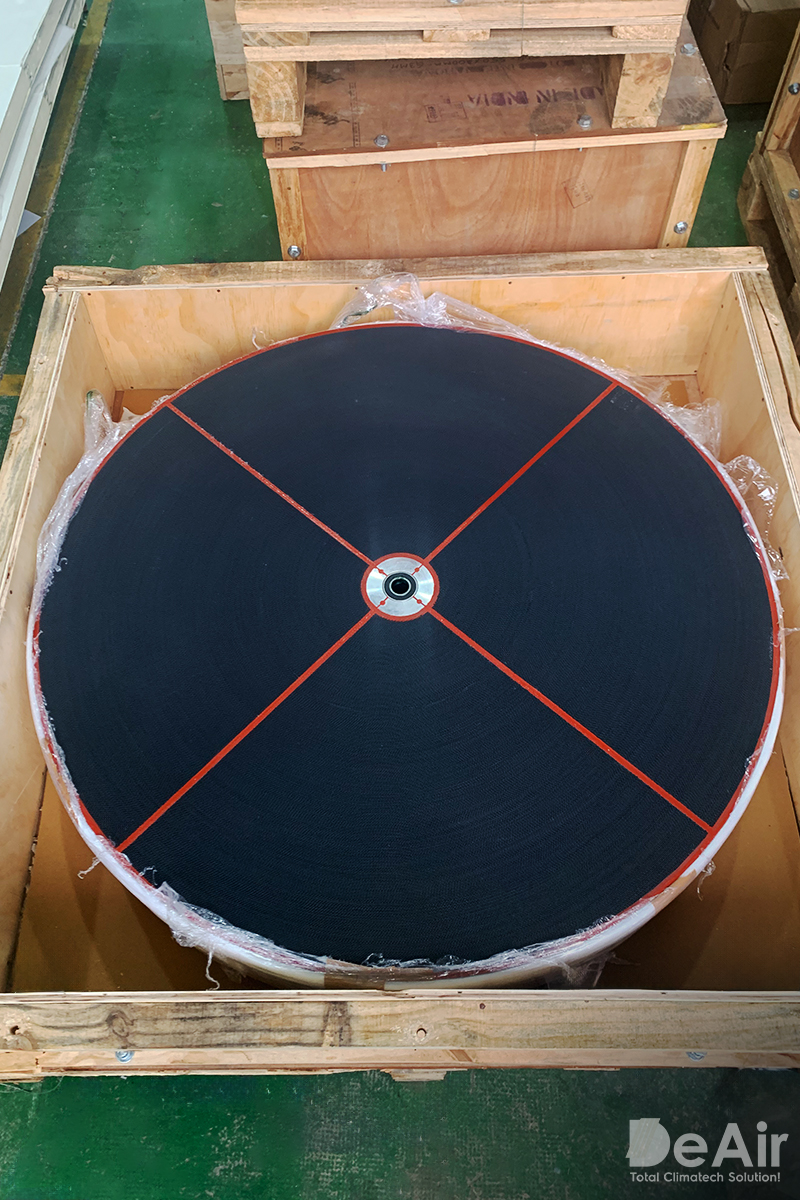

The core and most important part that determines how this device works is the rotor. The rotor has a special structure, made of honeycomb ceramic material, with alternating layers of flat plates and corrugated plates. The rotor surface is impregnated with a desiccant, mainly activated silica gel. This structure creates a large number of parallel axial air channels. As the humid air passes through these channels, the moisture is effectively absorbed, which is the first stage in the operating principle of the rotor dehumidifier.

Dehumidifying rotor

In addition to the rotor, the dehumidifying unit also includes a regeneration box, a regeneration fan and a driving motor. All these parts work together to ensure high dehumidification performance and durability for the device, based on the optimally designed operating principle.

Learn more about the operating principle of the Dezenno Rotor dehumidifier

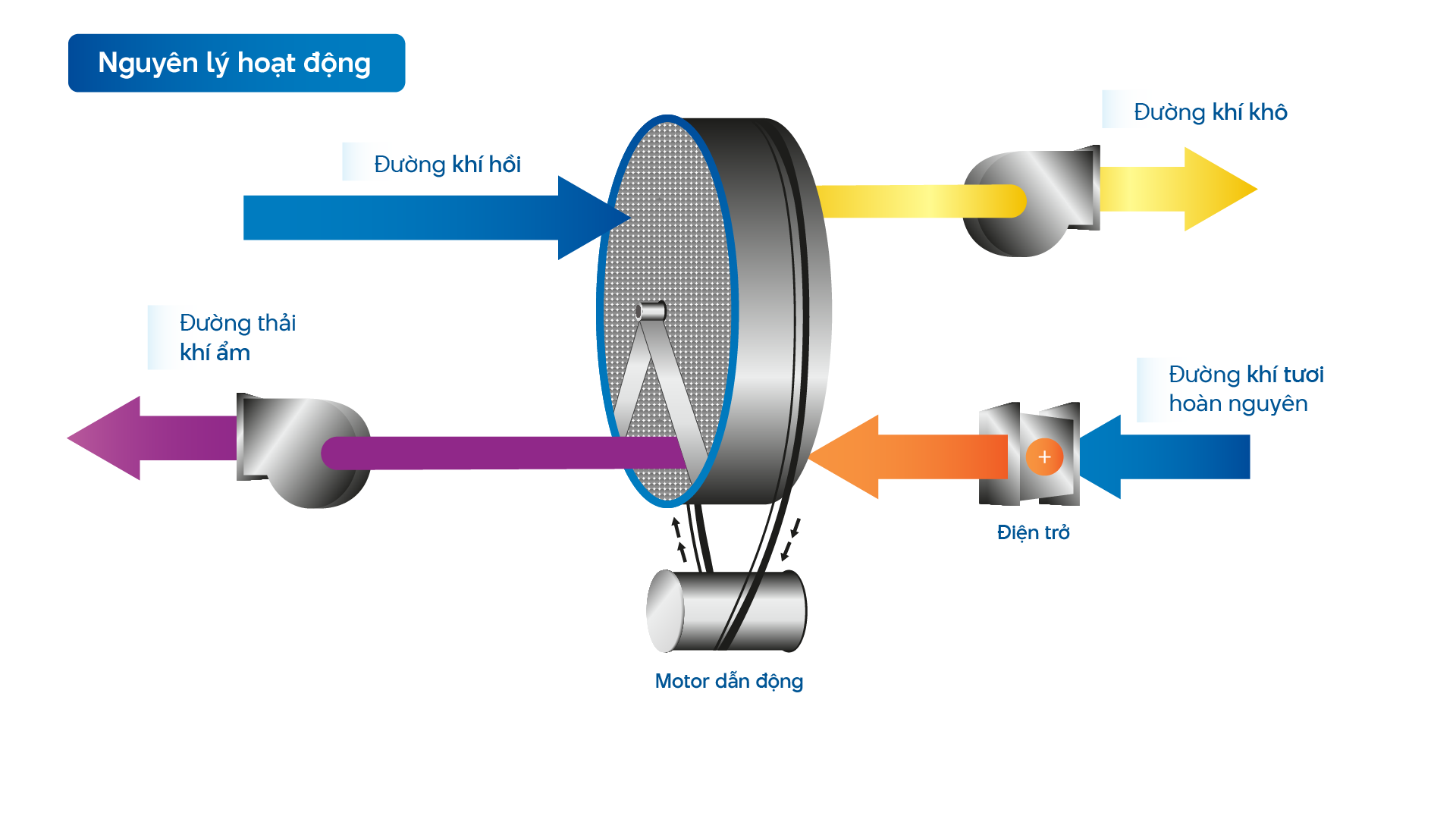

For easy visualization In this context, you can think of the Dezenno dehumidifier using a rotor combined with a condenser as a giant "breathing machine", continuously sucking in humid air and releasing dry air. The closed cycleThis system works based on the combination of two main processes that take place simultaneously on the rotor:

- Cooling and dehumidification stage: First, humid air from the environment to be treated is sucked into the Dezenno dehumidification device and passes through the primary evaporator. This evaporator acts as a "cooling door", helping to lower the air temperature, thereby increasing the dehumidification efficiency of the rotor by up to 25%. Next, the cooled air will be led through the dehumidifying rotor - the "heart" of the system. The rotor surface is filled with dehumidifying particles, when the air passes through, the moisture will be retained. At this point, the air has become drier, but the temperature may increase slightly due to the moisture absorption process. Therefore, the dry air continues to pass through the evaporator behind the rotor to be cooled to the desired temperature before being supplied back to the room. This is an important part of the operating principle to achieve the target humidity and temperature.

- Dehumidifying rotor regeneration stage: In order for the rotor to continue the dehumidifying process, it needs to be "regenerated" in its dehumidifying ability. Air from the outside environment is drawn into the device, passing through a filter to remove dirt. Then, this air is heated by a resistor to about 110°C. This hot air stream is blown over the rotor section that is filled with the moisture absorbed in the previous stage. The high temperature will heat the rotor surface in the regeneration chamber, increasing the water vapor pressure inside the rotor compared to the regeneration air stream. This helps release the trapped moisture, and this moisture is released into the environment along with the hot air stream. This regeneration process is an indispensable step in the operation of the Dezenno dehumidifier, ensuring that the device can operate continuously and effectively.

Thus, the two processes of cooling - dehumidifying and rotor regeneration take place in parallel and continuously on different parts of the rotating rotor, helping the Dezenno dehumidifier maintain stable humidity in the space to be controlled.

Outstanding advantages thanks to the unique operating principle of the Dezenno Rotor dehumidifier

Thanks to its special structure and advanced operating principle, the Dezenno rotor dehumidifier offers many outstanding advantages compared to other dehumidification technologies:

- Precise humidity control: The device is capable of controlling humidity at a very high level of precision, meeting the strict requirements of many specific industries.

- Effectively prevents condensation: Maintaining an extremely low dew point helps protect products and equipment from the negative effects of moisture, an important advantage derived from the operating principle of controlling both relative and absolute humidity.

- Smooth operation, energy saving: The optimized design of components and operating principles helps to minimize noise during operation and consume power effectively results.

- High durability, easy installation and maintenance: The equipment is made from high quality materials, ensuring a long service life and making maintenance and servicing simpler.

In short, the Dezenno rotor humidity treatment equipment is the optimal solution for humidity control in industries requiring high precision. With the ability to effectively control humidity, prevent condensation, operate smoothly and save energy based on the superior operating principle, the device brings outstanding cost efficiency and peace of mind to businesses.

See more: Industrial Rotor Dehumidifier For Factories: Effective, Durable | DeAir

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)