- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

Green Drying for Export: Daxwell Heat-Pump Dryer & The Key to Conquering ESG Standards

21/11/2025

Sustainable Export: When "Green Drying" Becomes a Vital Command

According to the Ministry of Industry and Trade Portal, green transformation is an inevitable trend. Demanding export markets like the EU, USA, and Japan are erecting increasingly strict "green barriers," most notably the Carbon Border Adjustment Mechanism (CBAM). Now, Vietnamese enterprises need not only good products but must also prove a production process with low carbon emissions and sustainability according to ESG standards (Environmental - Social - Governance).

In agricultural and food processing, the DRYING stage is often the most energy-consuming. If businesses continue to use old technologies (coal/wood stoves or resistance heaters), they face the risk of high taxes or import refusal. DeAir's Daxwell Heat-Pump Dryer is the "passport" helping businesses solve this problem.

Table of Contents

- 1. The "E" (Environmental): The Energy Saving & Emission Reduction Equation

- 2. Infographic: How Daxwell Helps Businesses Meet ESG Standards

- 3. The "S" (Social): Improving Working Environment & Safety

- 4. The "G" (Governance): Transparency in Technology & Origin

- 5. Installation Flexibility & Multi-Industry Application

- 6. Frequently Asked Questions (FAQ)

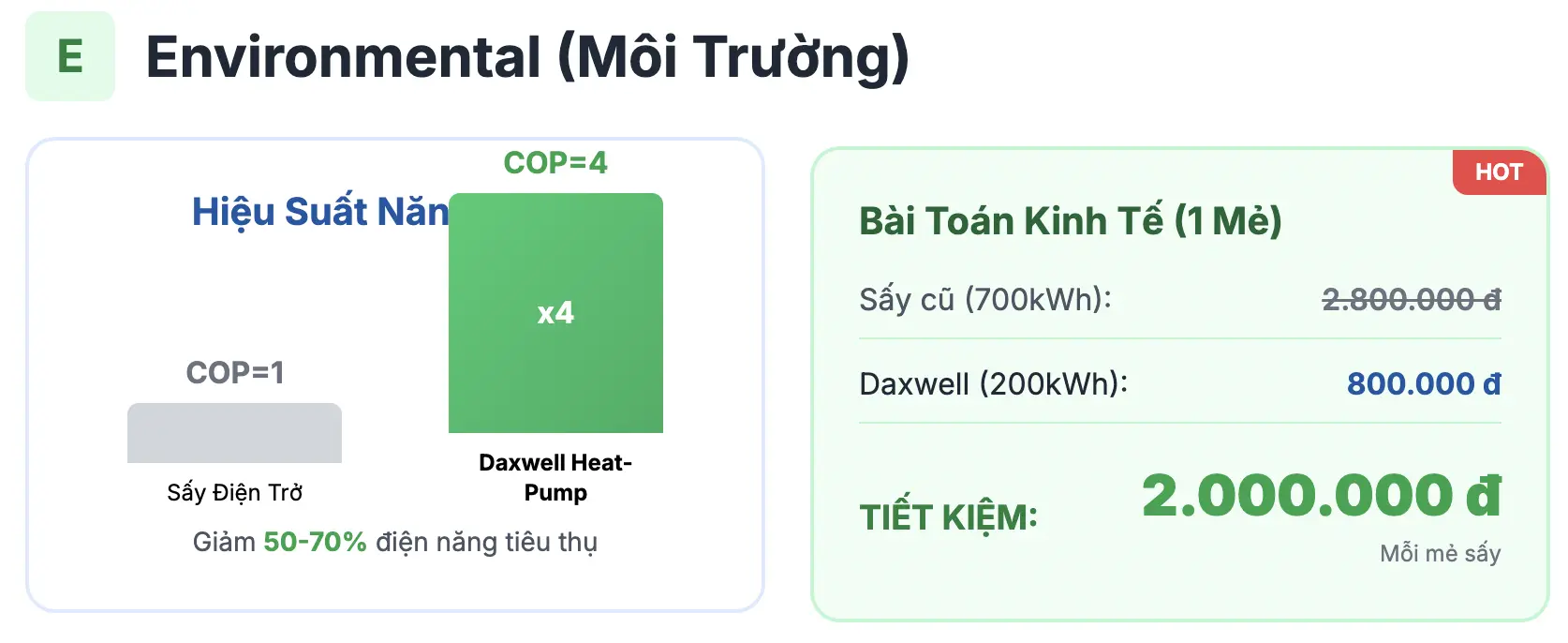

1. The "E" (Environmental): The Energy Saving & Emission Reduction Equation

Maximum Energy Efficiency

Compared to resistance drying (COP=1 efficiency, consuming 100% electrical energy to create heat), the Daxwell Heat-Pump Dryer achieves a COP of 3-4. This means the machine consumes only 1 part electricity to generate 3-4 parts useful heat energy thanks to the heat recovery mechanism. This helps reduce 50-70% of electricity consumption, directly reducing indirect CO2 emissions from power plants.

Real-World Calculation Example (Electricity cost approx. 4,000 VND/kWh)

Suppose a business needs to dry 1 ton of product/batch, requiring the removal of about 500kg of water:

- Old Method (Resistance Drying): Consumes about 700 kWh.

➔ Cost: 700 x 4,000 VND = 2,800,000 VND/batch. - Daxwell Method (Heat-Pump): Consumes about 200 kWh.

➔ Cost: 200 x 4,000 VND = 800,000 VND/batch.

Result: Saving 2,000,000 VND per drying batch. If running continuously for 300 batches/year, the business saves 600 Million VND. With a larger scale, savings can reach billions of VND annually, while contributing significantly to carbon reduction reports.

2. Infographic: How Daxwell Helps Businesses Meet ESG Standards

🌱

E - ENVIRONMENTAL

- Saves 50-70% energy.

- Reduces indirect CO2 emissions.

- Zero emissions, zero smoke/dust.

👷

S - SOCIAL

- Absolute fire safety.

- Cool working environment.

- Protects worker health.

📊

G - GOVERNANCE

- Transparent origin (CO/CQ).

- Digitized drying data (PLC).

- Meets export standards.

3. The "S" (Social): Improving Working Environment & Safety

Daxwell dryers operate entirely on electricity in a closed cycle:

- No smoke, dust, or toxic fumes: Completely eliminates health risks for workers compared to operating coal or wood furnaces.

- Cool environment: Thanks to excellent insulation, the machine does not radiate excess heat into the factory, improving working conditions (an important CSR criterion).

- Fire safety: Eliminates fire risks associated with combustion fuels.

4. The "G" (Governance): Transparency in Technology & Origin

Warning Against the "Big Shell - Small Engine" Reality

Many cheap imported dryer models on the market have bulky casings, giving a "heavy-duty" impression. However, inside there is often a lot of empty space (just for trays), while the compressor engine – the heart of the machine – has a very small capacity. The consequence is a weak machine that takes too long to dry, wastes electricity, and spoils products. Inexperienced buyers can easily confuse shell size with actual capacity.

DeAir Daxwell: Real Power - Real Origin

DeAir is committed to transparency regarding technical specifications and "Made in Vietnam" origin. This helps businesses easily explain origin profiles (Rules of Origin) in free trade agreements (EVFTA, CPTPP). The intelligent control system also helps store data, facilitating drying process traceability.

5. Installation Flexibility & Multi-Industry Application

Unlike fixed, fully imported units, DeAir's Daxwell industrial dryers offer extremely high installation flexibility:

- Retrofitting existing rooms: DeAir can renovate and install Daxwell dryers into clients' existing drying ovens, saving initial investment costs.

- Standard Panel Room Installation: We provide drying room solutions assembled with insulated panels, ensuring hygiene, aesthetics, and best heat retention.

- Mobile Container Drying Rooms: We design drying systems integrated into containers for needs requiring mobility or outdoor placement.

6. Frequently Asked Questions (FAQ)

1. Does the Daxwell dryer help achieve green certificates?

Yes. Reducing energy consumption and eliminating direct emissions are critical factors helping businesses achieve environmental certifications like ISO 14001 or improve ESG scores.

2. Does DeAir support calculating electricity savings for my factory?

Absolutely. DeAir's engineering team will conduct a site survey, calculate current costs, and forecast exact savings when switching to Daxwell Heat-Pump technology, giving you a solid basis for investment decisions.

3. Which industries is this dryer suitable for?

Daxwell dryers are suitable for most key export industries such as: Agriculture (fruits, vegetables), Seafood, Herbal medicine, and Handicrafts (rattan, wood).

Invest in a Sustainable Future Today!

Don't let outdated drying technology hinder your international orders. Contact DeAir now for advice and calculate your specific energy savings.

DEAIR JOINT STOCK COMPANY

Email: operation@deair.com.vn

Hotline: +84 925 977 579 (Ms. Tam) | +84 914 205 850 (Ms. Hoa)

Website: deair.com.vn

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)