- Home

- About Us

- Products

-

Heat-Pump Dehumidifier DeAir

DeAir.RE

DeAir.RE -

Heat-Pump Dryer DeAir.RE-H

DeAir.RE-H

DeAir.RE-H -

Heat-Pump Stainless Steel Dehumidifier

DeAir.RE-INOX

DeAir.RE-INOX -

Heat-Pump Isothermal Dehumidifier DeAir.CRE

DeAir.CRE

DeAir.CRE -

Dezenno Dehumidifier

Dezenno

Dezenno -

Heat-Pump Ceiling Mounted Dehumidifier DeAir

DeAir.RE-CL

DeAir.RE-CL -

Dehumidifier Olmas

Olmas-OS

Olmas-OS -

Industrial Humidifier DeAir

DeAir.HM

DeAir.HM -

Heat-Pump Dryer Daxwell

Daxwell

Daxwell -

Electric Duct Heater DeAir

DeAir.Heat

DeAir.Heat -

Air Handling Unit Dezenno.MAX

AHU

AHU

-

- Services

- Projects

- Warranty – Maintenance

- News

- Contact

Comprehensive Dehumidification Solutions for All Types of Storage Facilities: From Hot Curing to Deep-Freeze Cold Storage

14/10/2025

Introduction: "One Technology Cannot Solve All Problems"

On one hand, you have bales of exported garments marred by mold stains. On the other, a scene of ice and frost covering the floors and cooling coils of a deep-freeze warehouse. Both are "temperature-controlled storage," so why are the problems so different? The answer lies in applying the wrong humidity control technology for each specific temperature range. Using a one-size-fits-all solution not only wastes investment but can also lead to compounded damage to your goods.

This article will serve as an in-depth guide, analyzing the unique humidity challenges within each type of storage facility (Hot - Ambient - Cool - Cold) and presenting the most precise technological solution from DeAir to protect your assets and optimize operations.

Table of Contents

- 1. Understanding Temperature-Controlled Storage: More Than Just a Giant Refrigerator

- 2. The Humidity Problem: A Shapeshifting Enemy at Every Temperature Range

- 3. "The Right Cure for the Right Ailment": Choosing the Correct Dehumidification Technology

- 4. DeAir - Providing "Tailor-Made" Solutions for Every Storage Type

- 5. Frequently Asked Questions (FAQ)

1. Understanding Temperature-Controlled Storage: More Than Just a Giant Refrigerator

What is "Temperature-Controlled Storage"? Classification by Industry Standards

The essence of temperature-controlled storage is the maintenance of a stable temperature, whether hot or cold, to preserve goods. Based on their operating temperature ranges, these facilities are classified into key categories:

- Hot Storage (> 40°C): For processes like drying, curing, and vulcanizing products.

- Ambient / Finished Goods Storage (> 15°C): For general goods such as garments, handicrafts, paper, etc.

- Cool Storage (2°C to 15°C): For pharmaceuticals, fruits and vegetables, fresh flowers.

- Cold & Freezer Storage (< 0°C): For frozen foods, seafood, and vaccines.

2. The Humidity Problem: A Shapeshifting Enemy at Every Temperature Range

In Hot Storage (> 40°C): The Challenge of Uneven Drying

In drying rooms, applying heat without controlling humidity causes the air to quickly become saturated with moisture. This slows down the drying process, resulting in unevenly dried products (dry on the outside, still damp inside), which are prone to reabsorbing moisture and spoiling.

In Ambient Storage (> 15°C): Mold and Quality Degradation

This temperature range is an ideal breeding ground for mold and bacteria when humidity exceeds 70% RH. This leads to yellow stains on garments, deformation of handicrafts, softened paper packaging, and a general loss of product value. As experts from Dantherm Group, a leading global manufacturer, state, effective humidity control is central to successful warehouse storage.

In Cool & Cold Storage (< 15°C): Condensation, Frost, and the Vicious Energy Loop

When warm, moist air from outside infiltrates the space, water vapor condenses and instantly freezes onto the coldest surfaces, primarily the cooling coils. This creates a disastrous cycle: the ice acts as an unwanted "insulating jacket," forcing the cooling system to work harder and consume more power. The system must then run energy-intensive defrost cycles, causing temperature fluctuations that can harm products. Furthermore, condensation on floors creates hazardous, slippery conditions for workers and forklifts.

3. "The Right Cure for the Right Ailment": Choosing the Correct Dehumidification Technology

Selecting the right dehumidification technology is a strategic move that determines both effectiveness and long-term costs.

Solution for Finished Goods & Hot Storage (>15°C): The DeAir.RE-H Heat Pump Dryer

For ambient temperature warehouses storing goods like garments and handicrafts, or for hot storage and drying rooms, the DeAir.RE-H Heat Pump Dryer (formerly the heat-resistant dehumidifier) is the optimal solution. This technology not only effectively removes moisture across a wide temperature range (5-60°C) but also utilizes heat from the compressor. This makes the outlet air warmer, aiding the drying process or maintaining warehouse temperature while being exceptionally energy-efficient. DeAir has successfully implemented this system for numerous export-oriented garment and handicraft businesses, ensuring 100% protection of product quality.

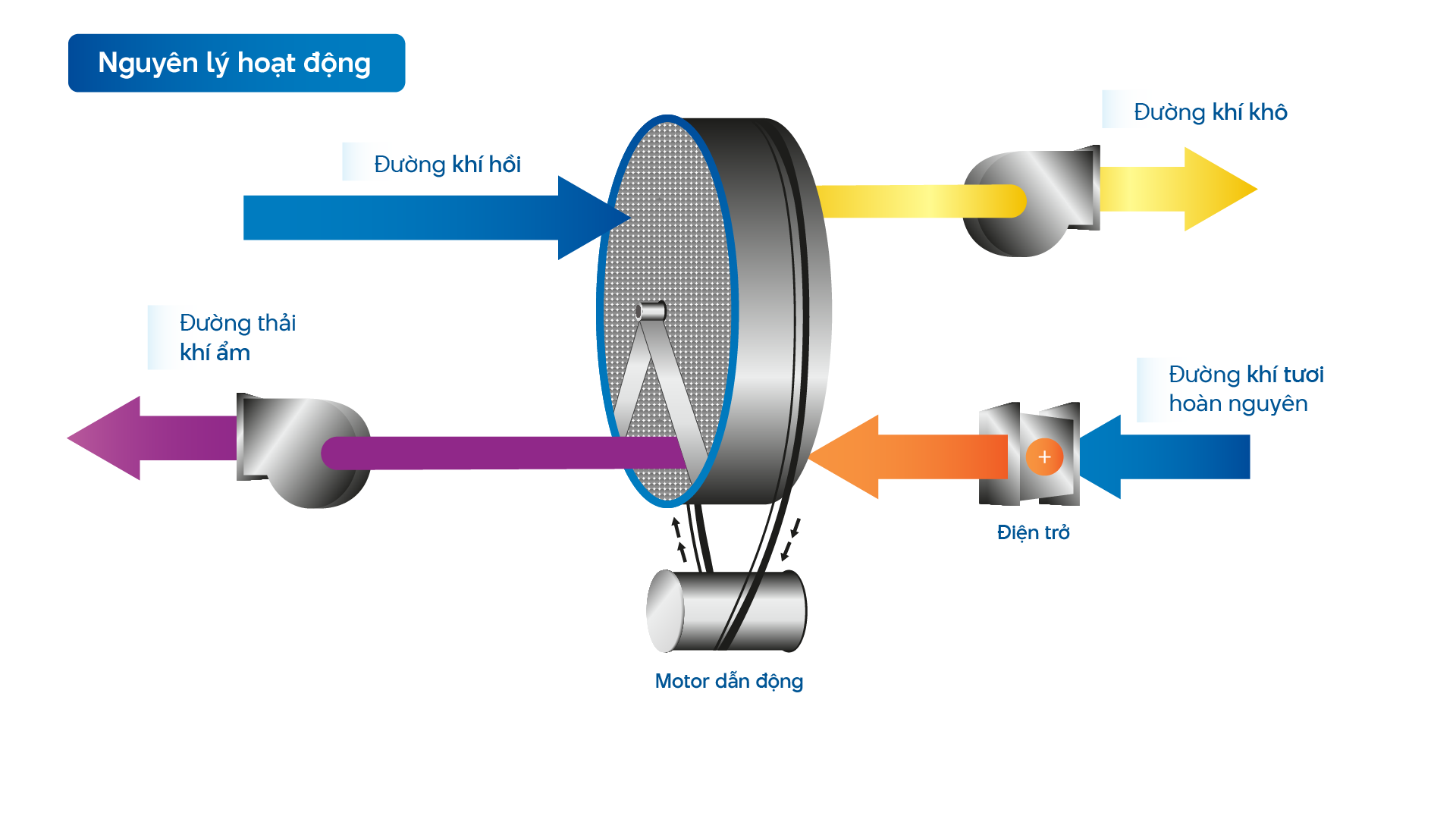

The Only Solution for Cold & Freezer Storage (<10°C): The Dezenno Rotor Dehumidifier

Why must it be a Rotor? Because a standard condensing dehumidifier is "useless" in a cold environment; its own cooling coil will simply freeze over. Only desiccant rotor technology, which absorbs moisture using silica gel and is not dependent on dew point, can operate effectively at low and sub-zero temperatures to prevent frost formation at its source. The Dezenno Rotor Dehumidifier line from DeAir is the specialized solution trusted by many frozen food and pharmaceutical companies to completely solve the problem of ice and frost.

The Advanced Solution for Cool Storage (2-15°C): The DeAir.CRE Isothermal Dehumidifier

In cool storage, a standard dehumidifier will add heat, forcing the main cooling system to work harder. The premium solution, the DeAir.CRE (Isothermal), was designed to solve this exact problem. By separating the heat-releasing condenser to an outside unit, it removes moisture without adding heat, allowing the cooling system to operate more efficiently and saving on total long-term energy costs.

4. DeAir - Providing "Tailor-Made" Solutions for Every Storage Type

DeAir doesn't just sell one type of machine; we offer a diverse range of technologies, selected and advised to best fit each client's specific problem.

Infographic: Choosing the Right DeAir Solution for Each Storage Type

HOT STORAGE (>40°C)

➔

DeAir.RE-H

(Heat-Resistant Heat Pump Dryer)

AMBIENT (>15°C)

➔

DeAir.RE / RE-H

(Heat Pump Dehumidifier/Dryer)

COOL (2-15°C)

➔

DeAir.CRE

(Isothermal Dehumidifier)

COLD/FREEZER (<0°C)

➔

Dezenno

(Rotor Dehumidifier)

5. Frequently Asked Questions (FAQ)

1. What is the main difference between cool storage and cold storage?

The main difference is the temperature range. Cool storage typically maintains temperatures above 0°C (commonly 2-15°C) to preserve products that need to be cool but not frozen. In contrast, cold storage maintains temperatures below 0°C to freeze and preserve frozen goods.

2. Why can't I use a standard dehumidifier for a freezer?

Because a standard dehumidifier (condensing technology) works by cooling the air. In a sub-zero environment, its own cooling coil will quickly freeze over and will no longer be able to condense moisture, rendering the machine completely ineffective.

3. How do I calculate the required dehumidifier capacity for my storage facility?

Sizing a dehumidifier for a storage facility is complex, depending on volume, insulation quality, door opening frequency, product traffic, and more. The best approach is to contact DeAir's expert team for a free on-site survey and consultation to ensure the correct capacity and technology are chosen, avoiding wasted investment.

Get a Specialized Consultation for Your Storage Facility

Whether you need to prevent mold in a garment warehouse or stop frost in a cold storage facility, let DeAir's experts help you choose the most suitable and effective technological solution.

DEAIR JOINT STOCK COMPANY

Email: operation@deair.com.vn

Hotline: +84 925 977 579 (Ms. Tam) | +84 914 205 850 (Ms. Hoa)

Website: deair.com.vn

Sign up for news from DeAir

Related news

![[Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong [Case Study] DeAir Installs DeAir.De Rotor Humidity Control System for Pharmaceutical Plant in Binh Duong](https://deair.com.vn/thumbs/news/2023_04/ban_giao_may_cho_duoc_bd/[270x153-cr]image1-1024x772.jpg__cv.webp)

![[Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses [Review & Guide] Olmas OS-300: The New Humidity Control "Warrior" for Medium to Large Warehouses](https://deair.com.vn/thumbs/news/huong_dan_su_dung_may_olmas_21/[270x153-cr]vtm06440.png)